All Categories

Unlocking the Potential of 3D Printers with Resin: A Comprehensive Guide for Professionals

2025-05-24 11:21

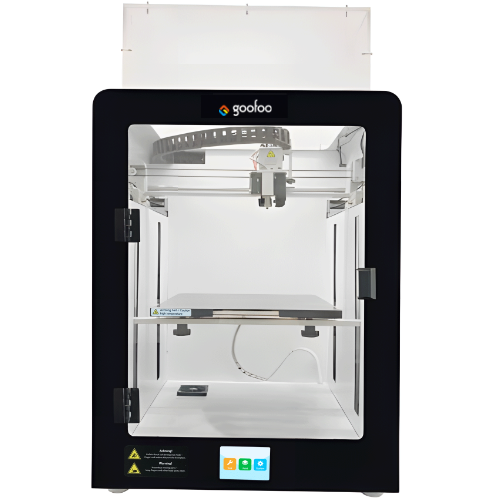

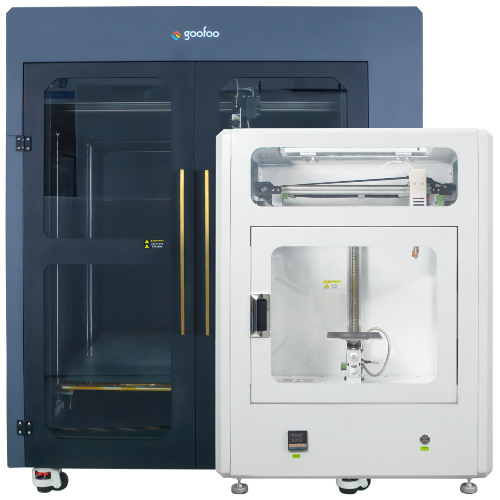

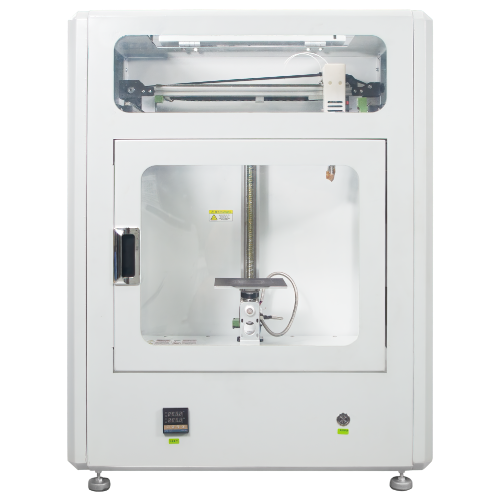

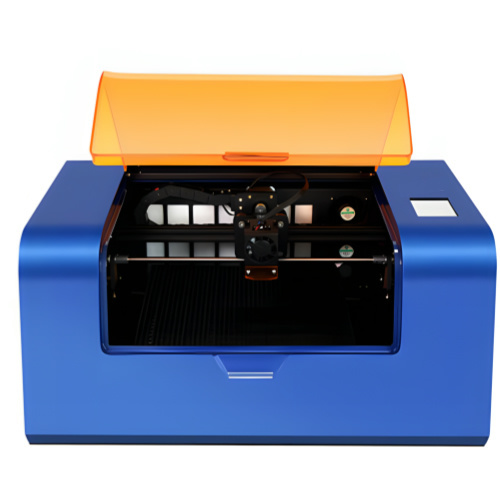

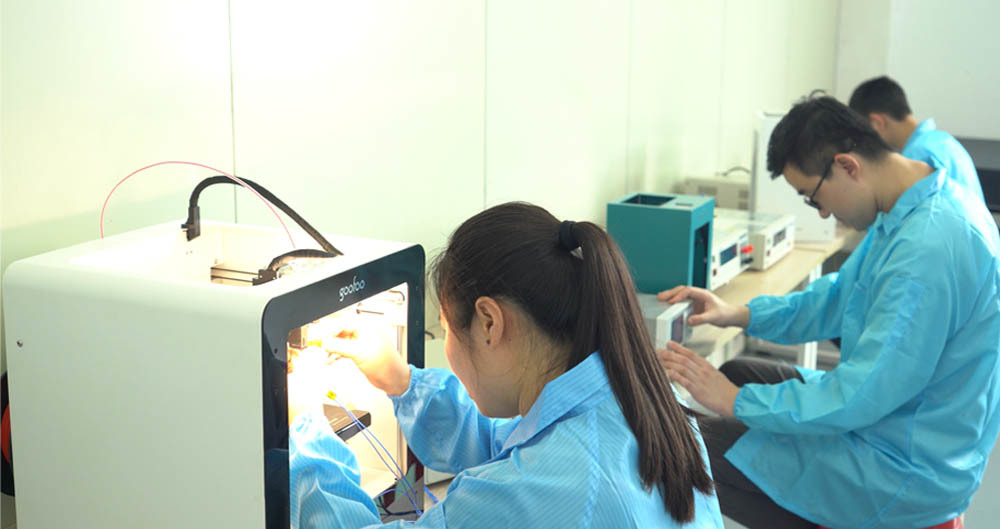

3D printing has revolutionized the manufacturing landscape, allowing for unprecedented levels of customization and complexity in production. Among the various types of 3D printing technologies, resin-based printers have gained significant attention for their ability to create highly detailed and intricate models. Understanding the nuances of 3D printers with resin can greatly enhance your projects and applications.

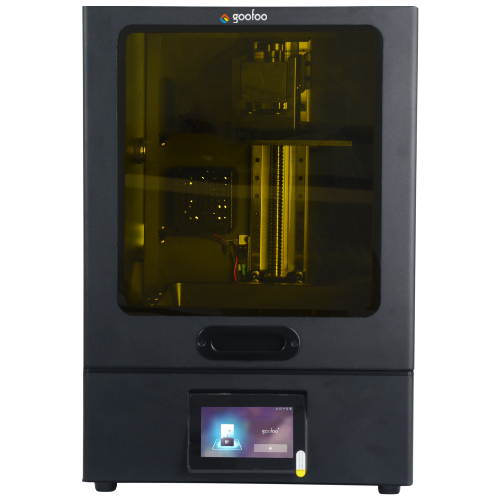

One of the standout features of resin 3D printers is their high resolution. Unlike filament-based printers, which extrude plastic, resin printers cure liquid resin layer by layer using UV light. This process enables the creation of models with fine details, smooth surfaces, and intricate geometries that are often unattainable with other methods. Industries ranging from jewelry design to dental applications frequently harness this capability to produce prototypes and end-use products that demand precision.

In terms of application, 3D printers with resin are particularly beneficial in sectors where accuracy is paramount. For instance, in the dental industry, practitioners use resin printing to create dental aligners and crowns that fit perfectly within a patient’s mouth. Similarly, engineers and designers utilize resin printers for prototyping complex components, ensuring that their designs are viable before moving to mass production.

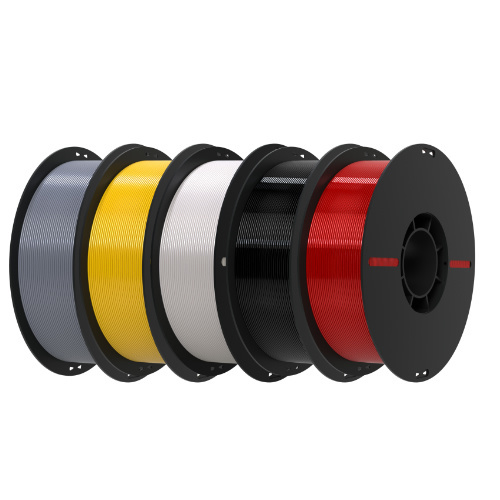

While the advantages are clear, there are considerations to keep in mind when selecting and using a resin 3D printer. First, it's essential to understand the different types of resin available, as they each offer unique properties that cater to specific applications. For example, some resins are designed for durability, while others may provide flexibility or heat resistance. Selecting the appropriate resin for your project can significantly impact the final product's performance.

Another critical factor is safety. The resin used in these printers can emit fumes and may cause skin irritation. Therefore, working in a well-ventilated area and wearing appropriate protective gear is crucial to ensure safety during the printing process.

Moreover, maintenance and post-processing are vital aspects of working with resin 3D printers. Unlike filament printers, models produced with resin require cleaning in isopropyl alcohol and often need post-curing under UV light to achieve optimal strength and durability. Incorporating these steps into your workflow can lead to superior results and extend the lifespan of your printed items.

In summary, 3D printers with resin stand out as a powerful tool for professionals seeking to push the boundaries of design and production. With their ability to produce high-resolution and detailed models, they serve a diverse range of industries. By understanding the material properties, safety protocols, and post-processing requirements, you can effectively harness the potential of resin 3D printing for your projects.

One of the standout features of resin 3D printers is their high resolution. Unlike filament-based printers, which extrude plastic, resin printers cure liquid resin layer by layer using UV light. This process enables the creation of models with fine details, smooth surfaces, and intricate geometries that are often unattainable with other methods. Industries ranging from jewelry design to dental applications frequently harness this capability to produce prototypes and end-use products that demand precision.

In terms of application, 3D printers with resin are particularly beneficial in sectors where accuracy is paramount. For instance, in the dental industry, practitioners use resin printing to create dental aligners and crowns that fit perfectly within a patient’s mouth. Similarly, engineers and designers utilize resin printers for prototyping complex components, ensuring that their designs are viable before moving to mass production.

While the advantages are clear, there are considerations to keep in mind when selecting and using a resin 3D printer. First, it's essential to understand the different types of resin available, as they each offer unique properties that cater to specific applications. For example, some resins are designed for durability, while others may provide flexibility or heat resistance. Selecting the appropriate resin for your project can significantly impact the final product's performance.

Another critical factor is safety. The resin used in these printers can emit fumes and may cause skin irritation. Therefore, working in a well-ventilated area and wearing appropriate protective gear is crucial to ensure safety during the printing process.

Moreover, maintenance and post-processing are vital aspects of working with resin 3D printers. Unlike filament printers, models produced with resin require cleaning in isopropyl alcohol and often need post-curing under UV light to achieve optimal strength and durability. Incorporating these steps into your workflow can lead to superior results and extend the lifespan of your printed items.

In summary, 3D printers with resin stand out as a powerful tool for professionals seeking to push the boundaries of design and production. With their ability to produce high-resolution and detailed models, they serve a diverse range of industries. By understanding the material properties, safety protocols, and post-processing requirements, you can effectively harness the potential of resin 3D printing for your projects.

3d printer with resin

Recommended News

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Skype / WhatsApp: +86 592-5713513 / +86-13860126490

No.88-3, North Tongji Road, Xike County, Tong'an District, Xiamen, Fujian China

Xiamen Goofoo Technology Co., Ltd. All Rights Reserved 闽ICP备2022008070号-1 SEO 300.cn

Phone:+0086 592-5713513

Address: No.88-3, North Tongji Road, Xike County, Tong’an District, Xiamen, Fujian China

Email: sales@goofoo3d.com

We will give you feedback in time