Unlocking the Potential of 3D Resin Printers: A Guide for Digital Product Professionals

2025-05-16 11:00

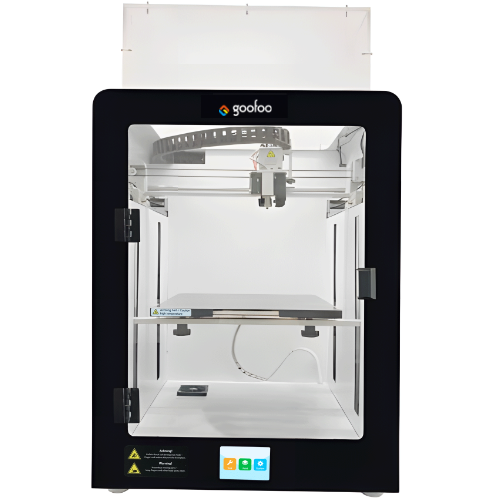

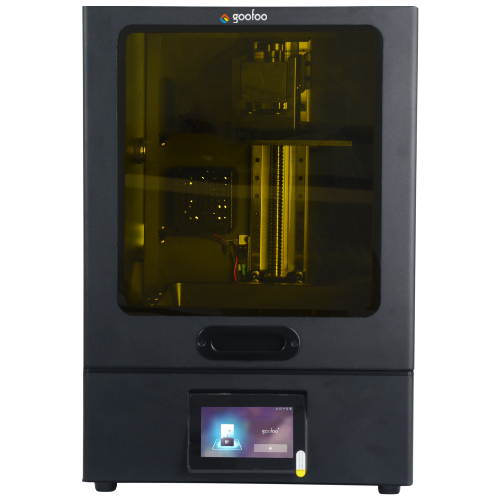

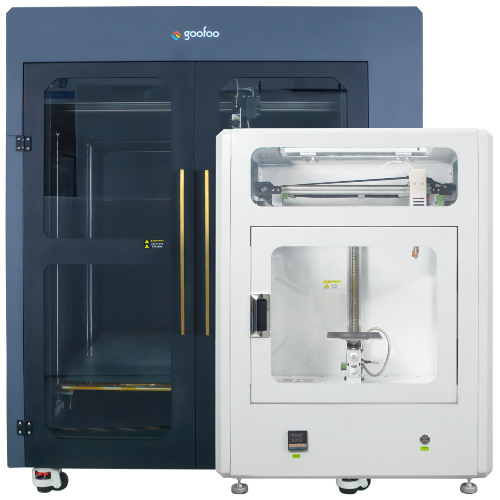

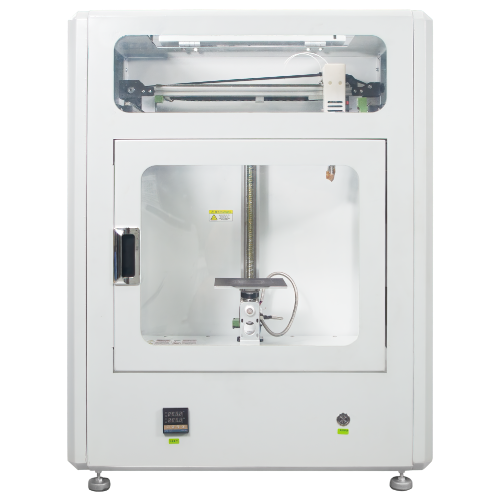

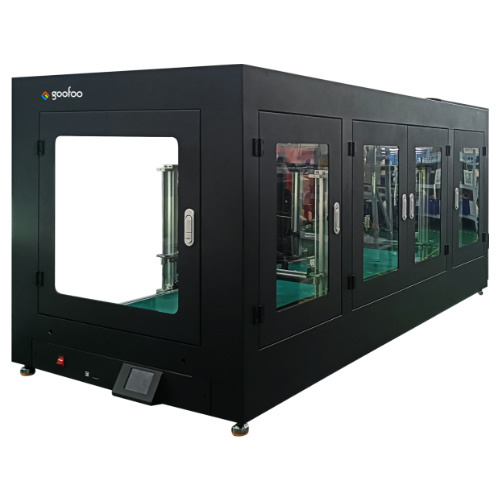

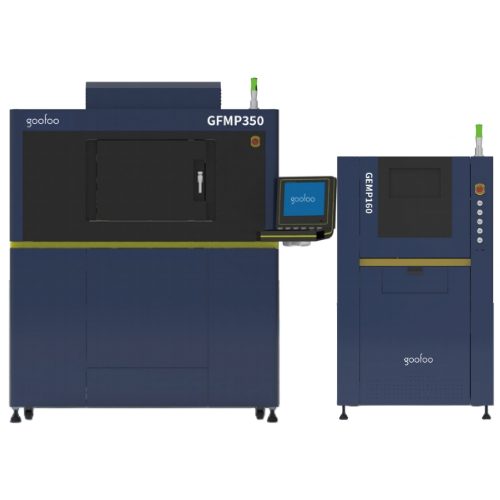

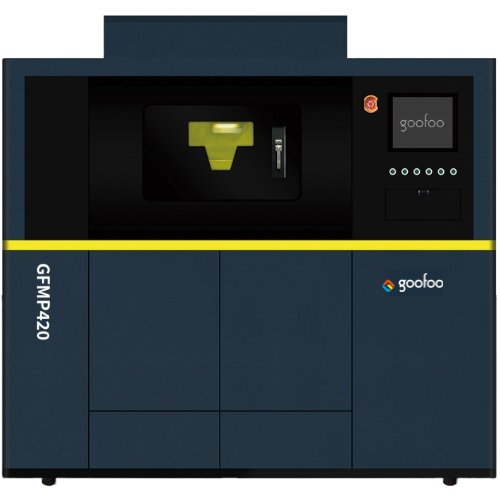

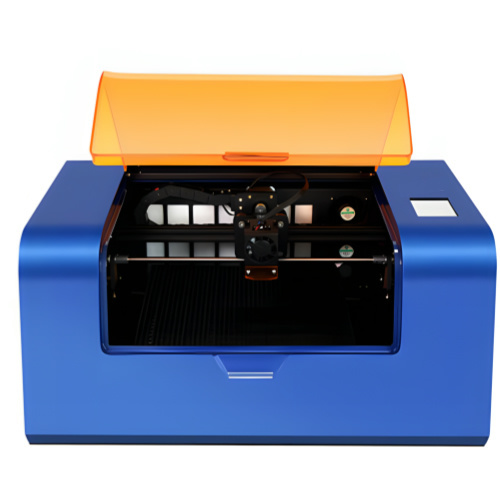

The advent of 3D resin printers has revolutionized the manufacturing landscape, offering unparalleled precision and adaptability for various applications in the computer digital products industry. Unlike traditional filament-based 3D printers, resin printers utilize liquid photopolymer resins that are cured by UV light, allowing for intricate designs and fine details that were previously challenging to achieve. Understanding this technology is essential for professionals looking to enhance their product development processes.

One of the primary advantages of 3D resin printing is its high resolution. This technology can produce objects with layer resolutions as fine as 25 microns, making it ideal for applications requiring intricate detailing, such as prototyping computer components or creating complex digital models. This level of detail is particularly beneficial in fields like gaming and film, where visual fidelity plays a crucial role.

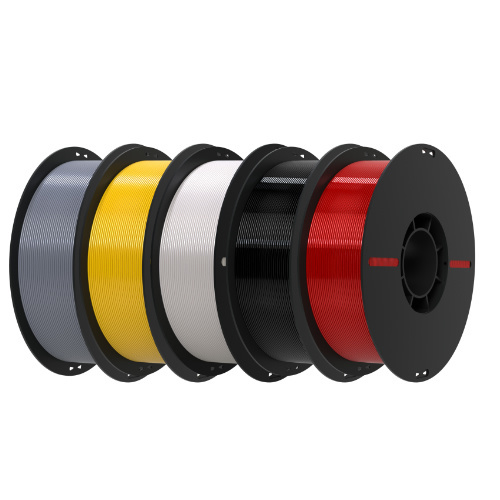

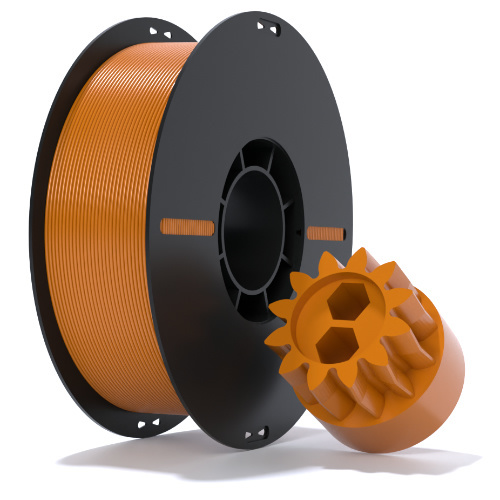

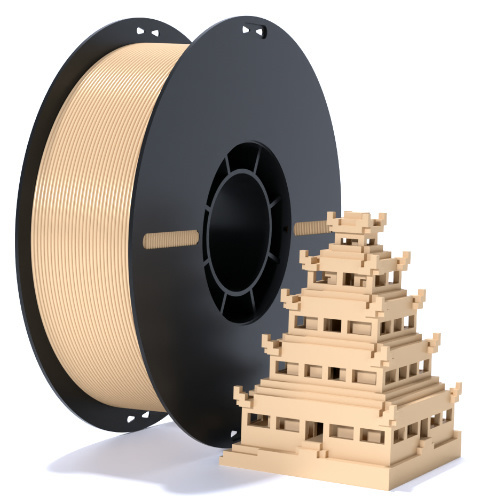

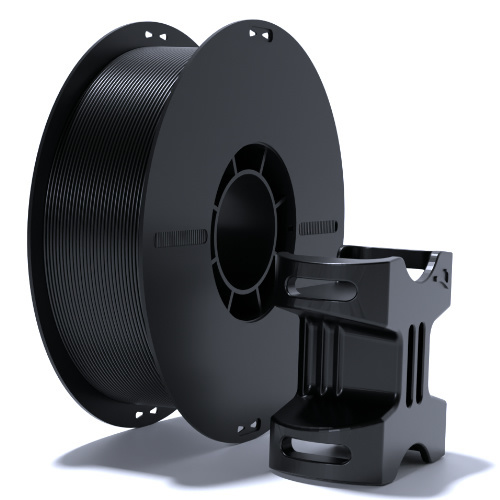

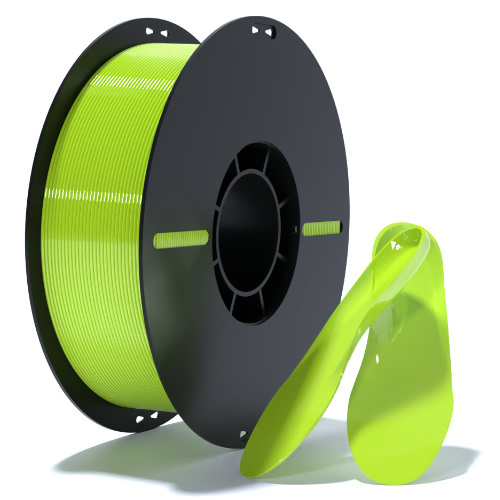

In addition to precision, 3D resin printers offer a range of materials that can be utilized, each with unique properties. For instance, standard resin is great for general prototyping, while flexible and durable resins can be used for functional parts that require elasticity or impact resistance. This versatility allows designers and engineers to select the right type of resin for their specific needs, enhancing the overall quality and performance of their products.

Another significant benefit of 3D resin printing is the speed of production. Unlike traditional manufacturing methods that often require extensive setup and tooling, resin printing can quickly produce parts from digital files. This rapid prototyping capability enables digital product professionals to iterate designs faster, reducing time to market and ensuring that products meet the evolving demands of consumers.

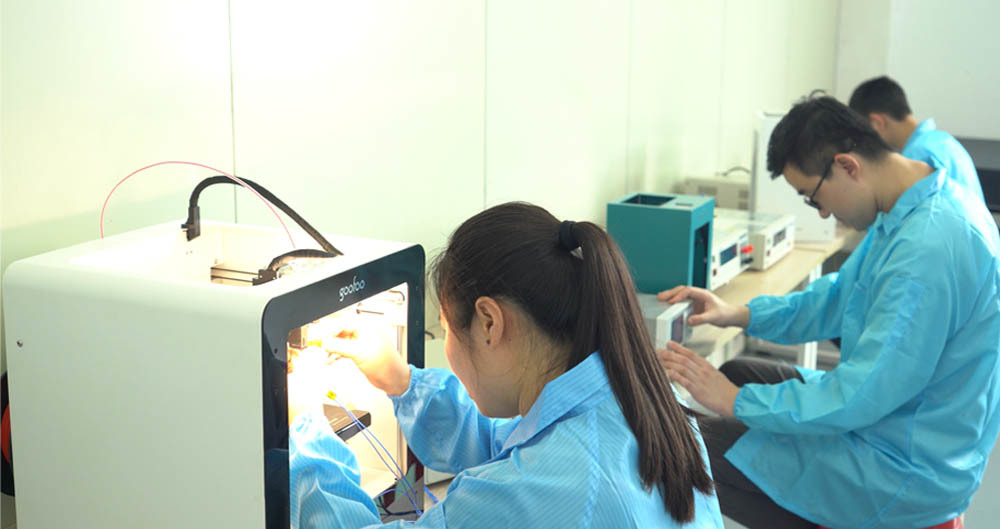

Furthermore, 3D resin printers are becoming increasingly user-friendly. Many models now come equipped with intuitive software that simplifies the design process, making it accessible even for those without extensive technical expertise. This democratization of technology allows teams to focus on creativity and innovation rather than being bogged down by complex manufacturing processes.

However, it is essential to consider the post-processing needs when using 3D resin printers. After printing, objects typically require cleaning in isopropyl alcohol and curing under UV light to achieve optimal strength and finish. Understanding these steps is crucial for ensuring the quality and durability of the final product.

In conclusion, incorporating 3D resin printers into your workflow can significantly enhance your capabilities in the computer digital products sector. With their ability to produce high-resolution, intricate designs quickly and efficiently, these printers are invaluable tools for professionals looking to stay ahead in a competitive marketplace. Embracing this technology not only improves product quality but also accelerates innovation, paving the way for future advancements in digital product creation.

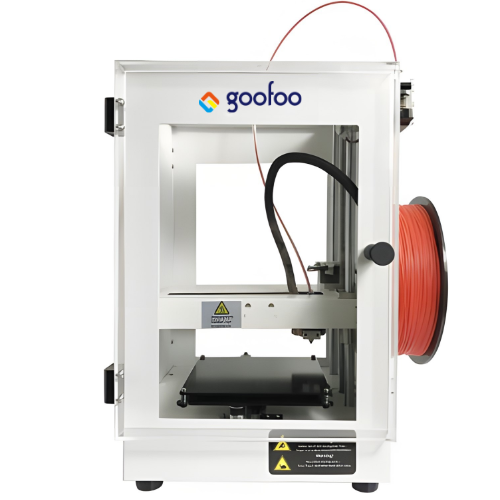

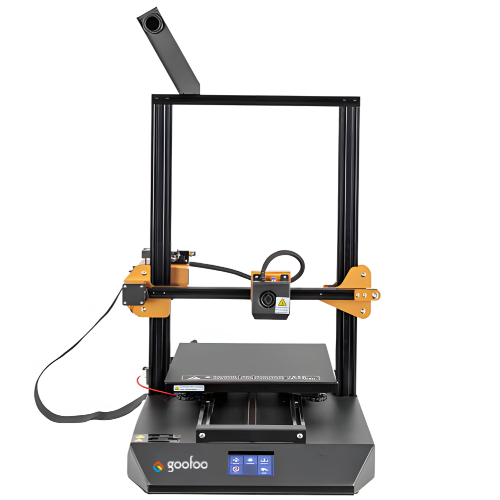

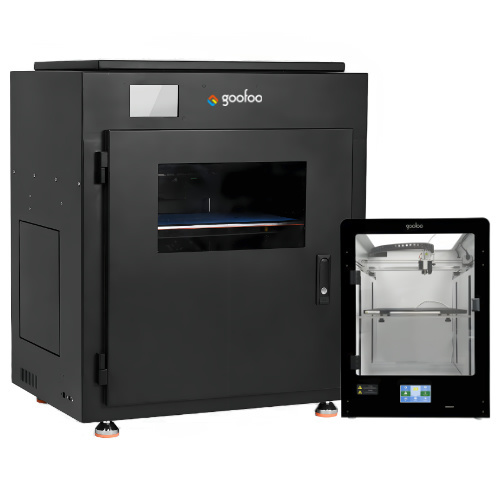

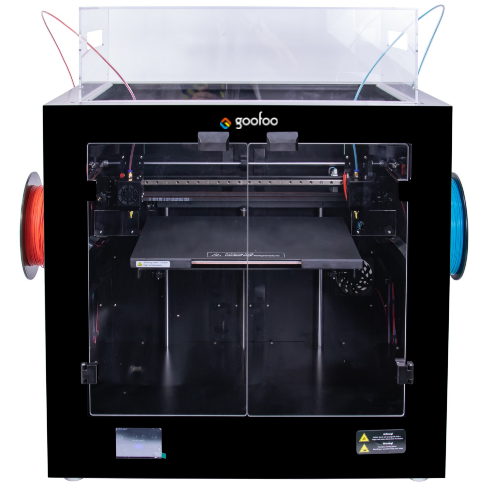

3d resin printer

Recommended News

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Skype / WhatsApp: +86 592-5713513 / +86-13860126490

No.88-3, North Tongji Road, Xike County, Tong'an District, Xiamen, Fujian China

Xiamen Goofoo Technology Co., Ltd. All Rights Reserved 闽ICP备2022008070号-1 SEO 300.cn

Phone:+0086 592-5713513

Address: No.88-3, North Tongji Road, Xike County, Tong’an District, Xiamen, Fujian China

Email: sales@goofoo3d.com

We will give you feedback in time