The Comprehensive Guide to FDM 3D Printing: Unleashing the Potential of Additive Manufacturing

2025-04-14 12:20

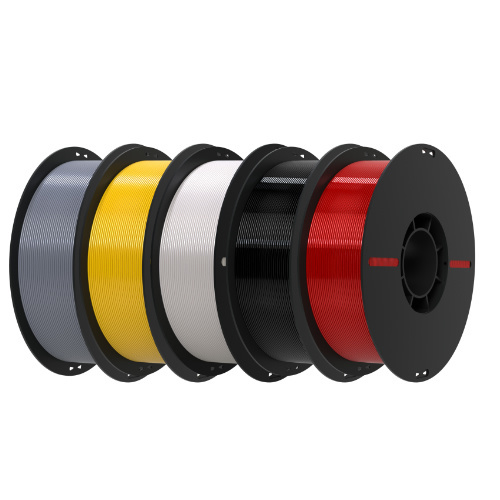

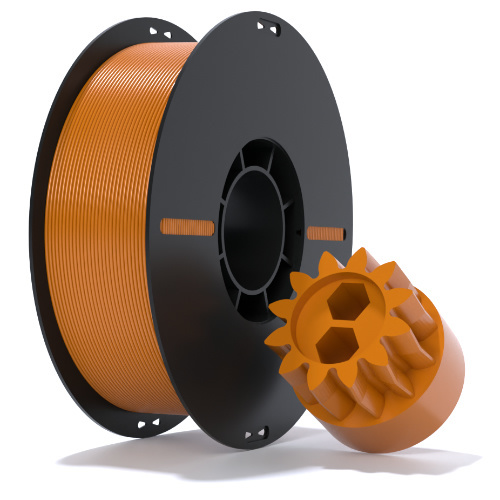

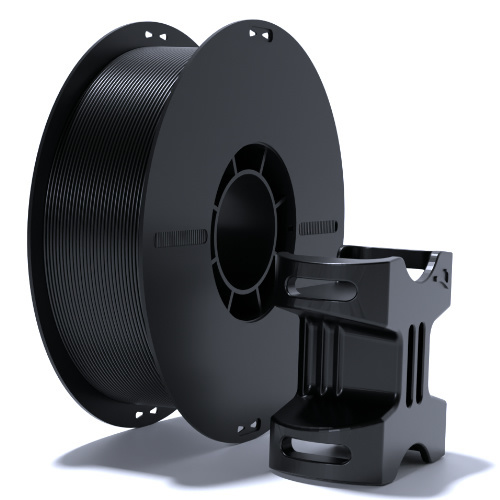

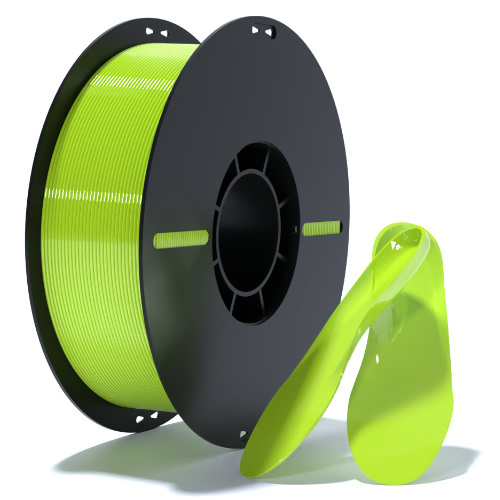

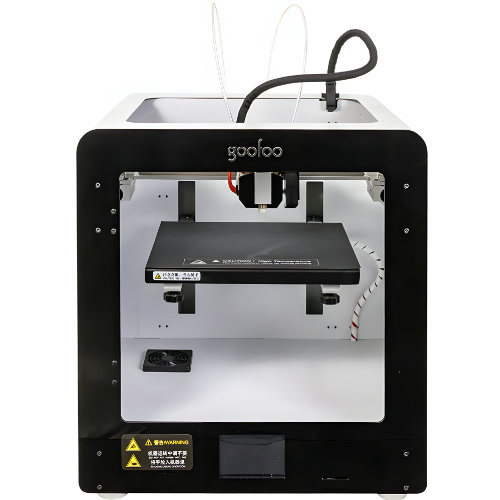

Fused Deposition Modeling (FDM) is one of the most widely used 3D printing technologies, particularly popular among both hobbyists and professionals. It works by melting thermoplastic filament and extruding it layer by layer to create a three-dimensional object. This process not only makes FDM printers versatile but also allows for a range of materials to be used, including PLA, ABS, PETG, and more.

One of the primary advantages of FDM 3D printing is its accessibility. The technology is relatively easy to set up and operate compared to other 3D printing methods, making it an excellent choice for beginners. Moreover, the extensive availability of materials and the ability to produce functional prototypes quickly have made FDM a go-to option across various industries.

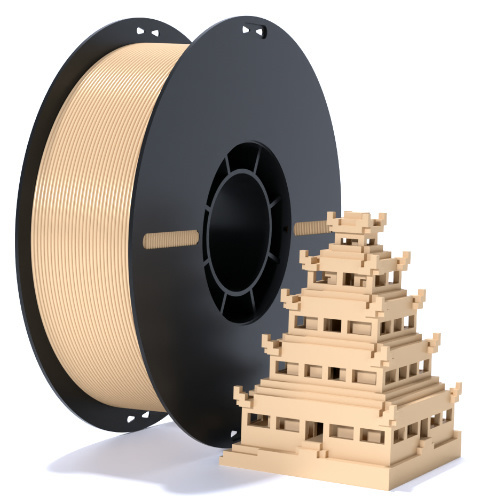

FDM printers can produce intricate designs and complex geometries that would be challenging to achieve with traditional manufacturing methods. This capability opens up new avenues for innovation, allowing designers and engineers to experiment with unique shapes and functional components without the constraints of conventional manufacturing processes. For instance, in industries such as automotive, aerospace, and medical, FDM can be used to create lightweight structures or customized components tailored to specific needs.

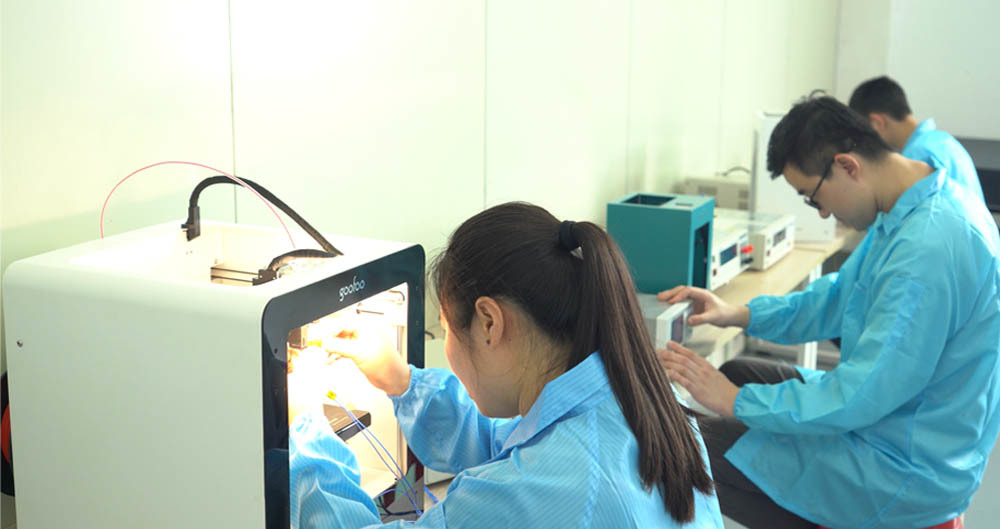

In terms of applications, FDM technology is used in product development, tooling, and even end-use parts. Rapid prototyping is one of the most notable uses, as it allows companies to test and iterate designs quickly. This efficiency not only saves time but also reduces costs associated with traditional prototyping methods. Moreover, FDM is increasingly being utilized in educational settings, providing students with hands-on experience in design and engineering.

However, it is essential to understand the limitations of FDM printing. The layer-by-layer construction can sometimes lead to visible layer lines, which may not be suitable for all applications, particularly those requiring smooth surfaces. Additionally, the strength of the printed parts can vary depending on the filament used, print settings, and the orientation of the print. Therefore, it is crucial to choose the right material and optimize the printing parameters to achieve the desired results.

In conclusion, FDM 3D printing offers a powerful and flexible solution for various applications in the computer and digital products sector. Its unique ability to quickly produce prototypes and functional parts makes it a valuable tool for professionals looking to innovate and streamline their processes. Understanding the capabilities and limitations of this technology can help users make informed decisions and maximize the benefits of FDM printing in their projects.

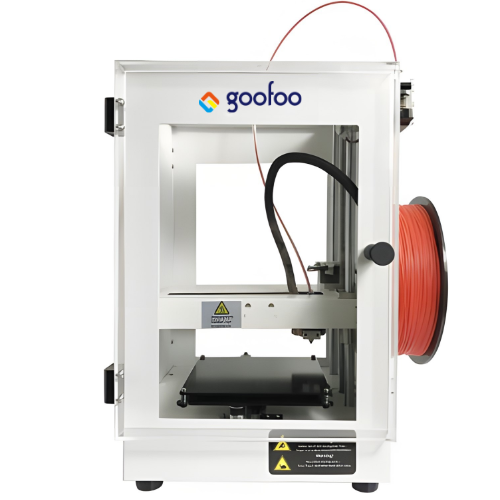

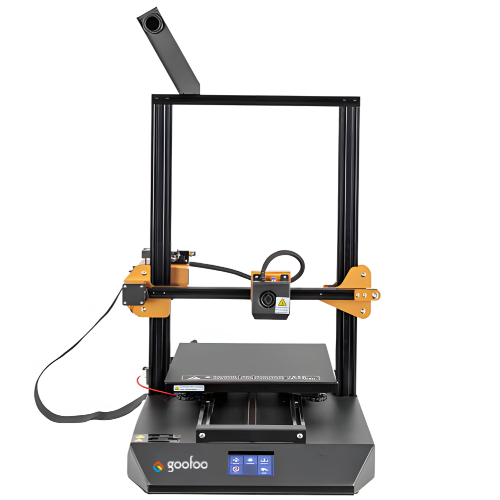

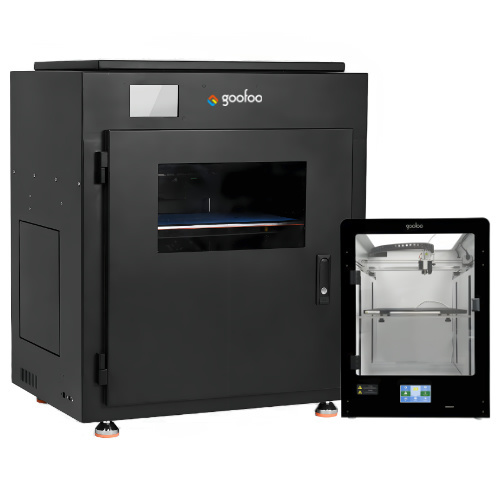

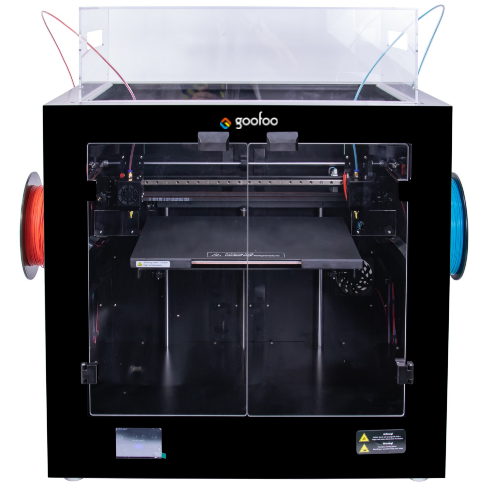

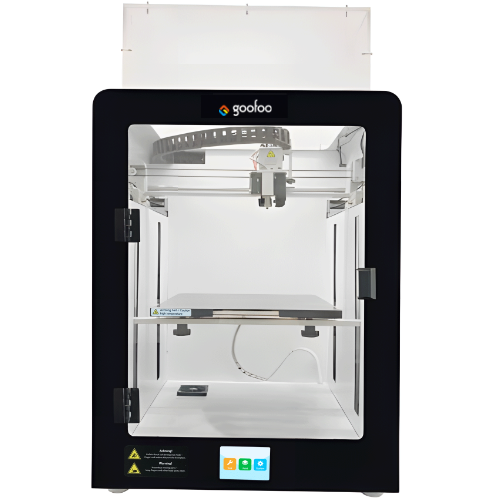

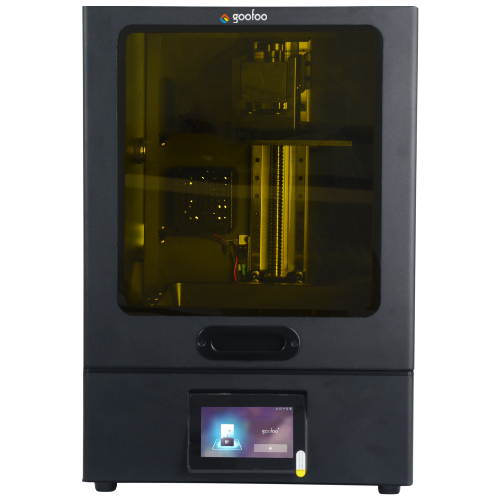

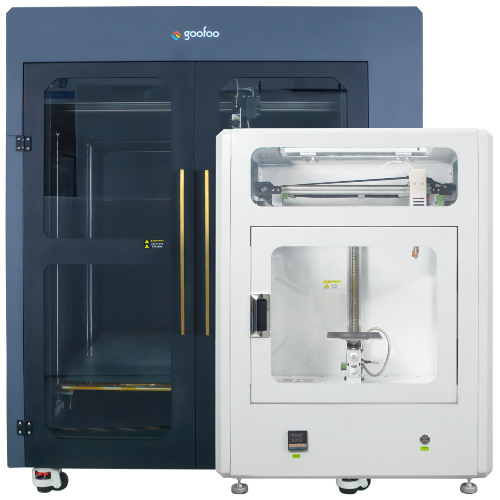

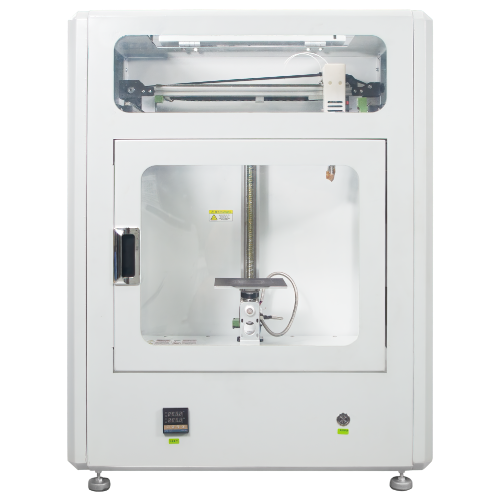

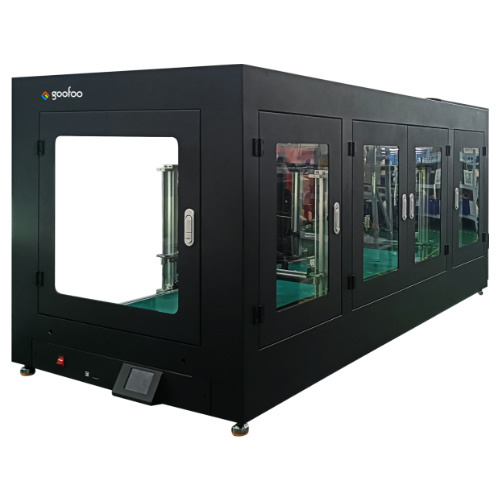

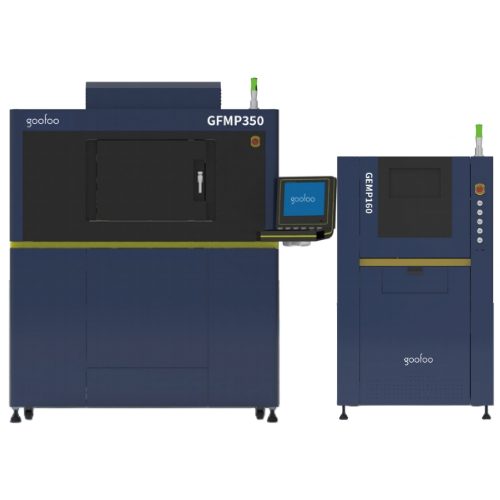

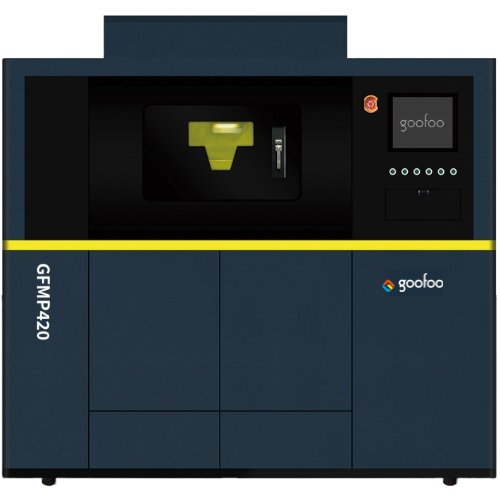

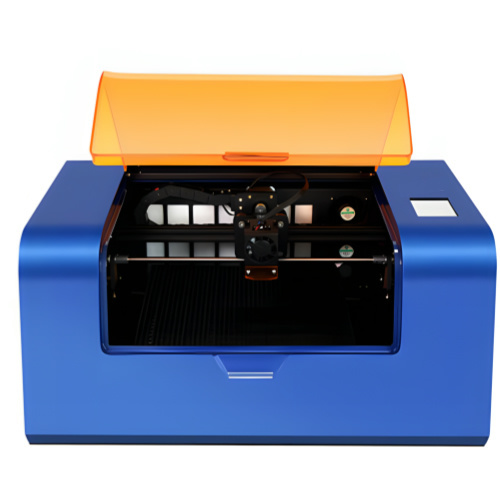

3d printer fdm

Recommended News

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Skype / WhatsApp: +86 592-5713513 / +86-13860126490

No.88-3, North Tongji Road, Xike County, Tong'an District, Xiamen, Fujian China

Xiamen Goofoo Technology Co., Ltd. All Rights Reserved 闽ICP备2022008070号-1 SEO 300.cn

Phone:+0086 592-5713513

Address: No.88-3, North Tongji Road, Xike County, Tong’an District, Xiamen, Fujian China

Email: sales@goofoo3d.com

We will give you feedback in time