All Categories

The Transformative Power of 3D Printer Machines: Revolutionizing Manufacturing and Design

2025-04-30 11:20

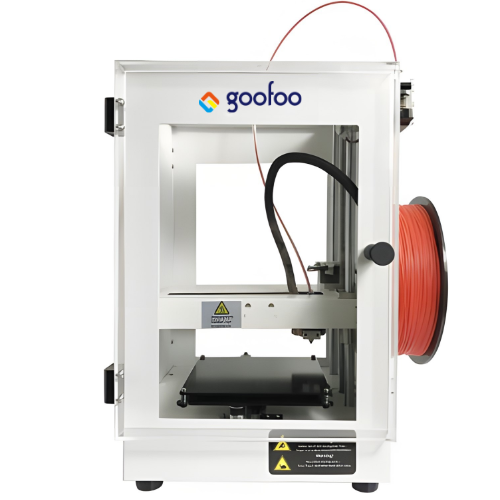

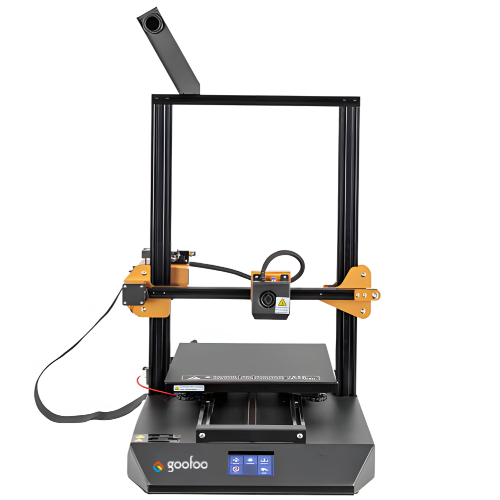

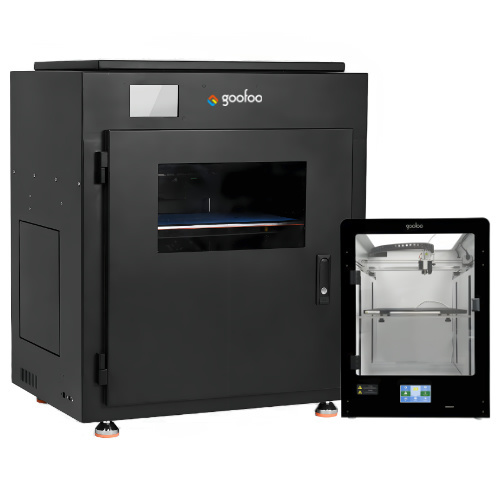

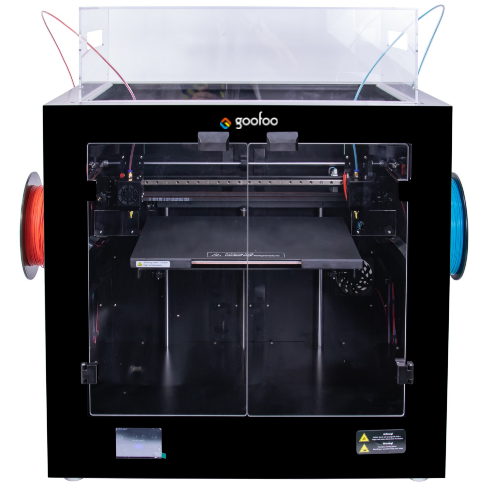

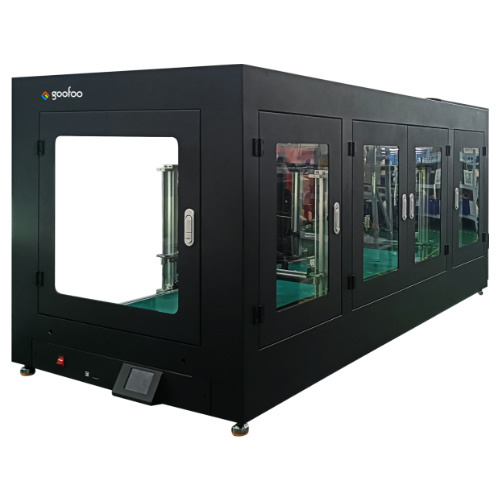

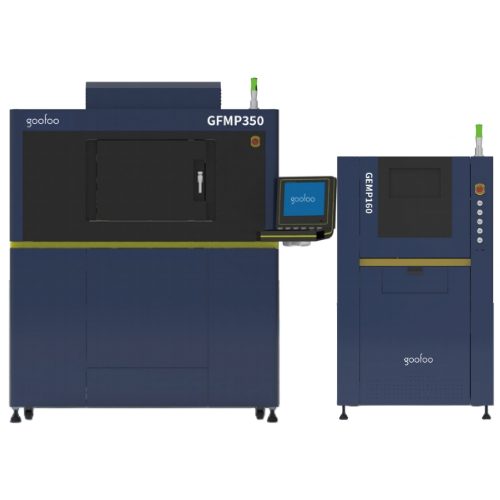

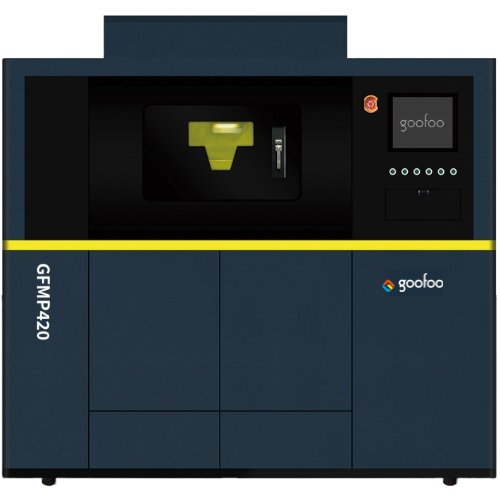

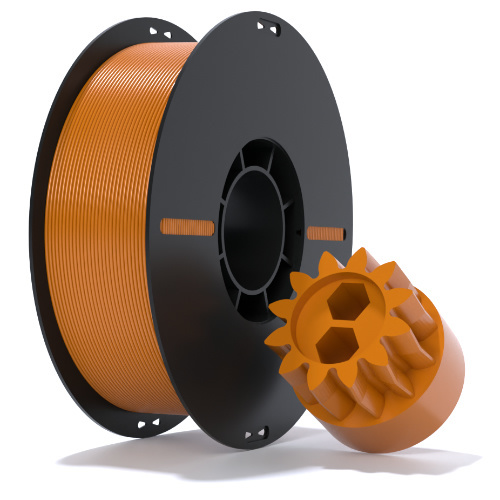

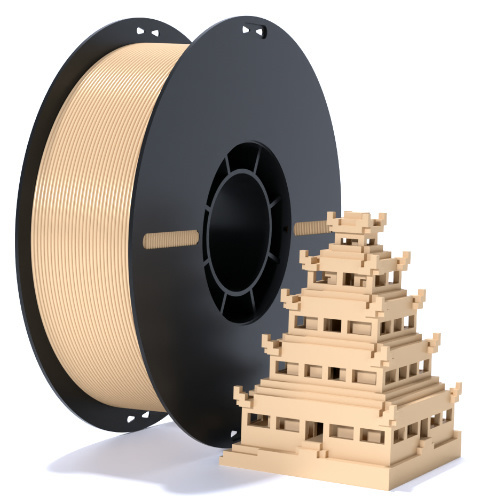

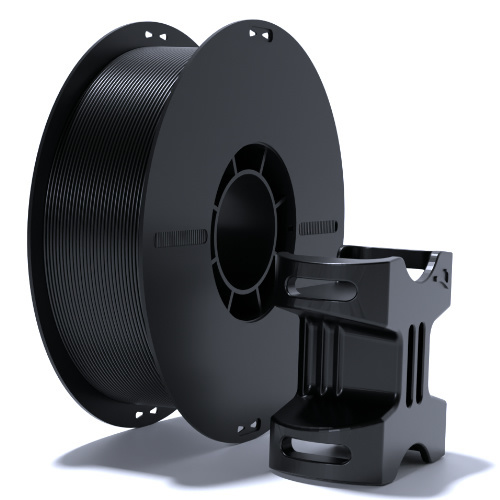

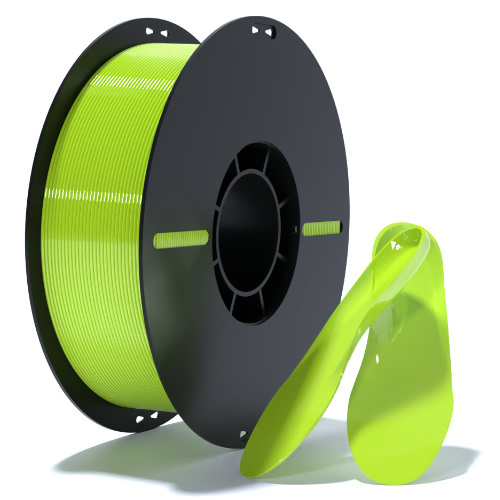

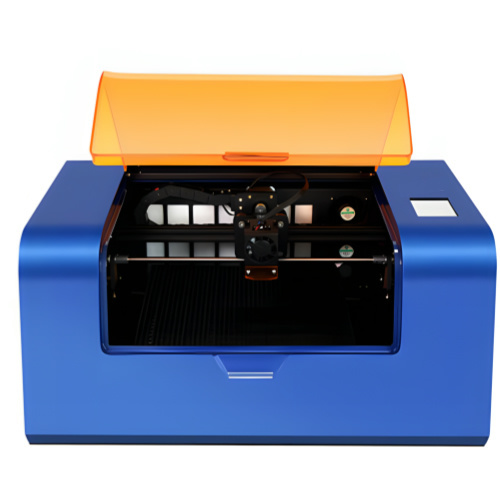

In recent years, 3D printer machines have revolutionized the way we approach manufacturing and design. These innovative devices allow users to create three-dimensional objects from digital files, enabling a level of customization and efficiency that traditional production methods cannot match. The core technology is additive manufacturing, where materials are added layer by layer to build up an object, which contrasts sharply with subtractive manufacturing processes that remove material to create a product.

One of the most significant advantages of 3D printer machines is their versatility. They can produce a vast array of items, from prototypes and spare parts to complex architectural models and consumer products. This flexibility makes them invaluable in various sectors, including automotive, aerospace, healthcare, and even fashion. For instance, in healthcare, 3D printers have been used to create custom prosthetics and dental implants tailored to the individual needs of patients, enhancing comfort and functionality.

Moreover, 3D printer machines facilitate rapid prototyping, allowing designers and engineers to iterate on their concepts much faster than traditional methods would allow. This speed can significantly reduce time-to-market for new products, giving companies a competitive edge. By quickly producing prototypes, teams can test functionality and design, gather feedback, and make necessary adjustments before committing to large-scale production.

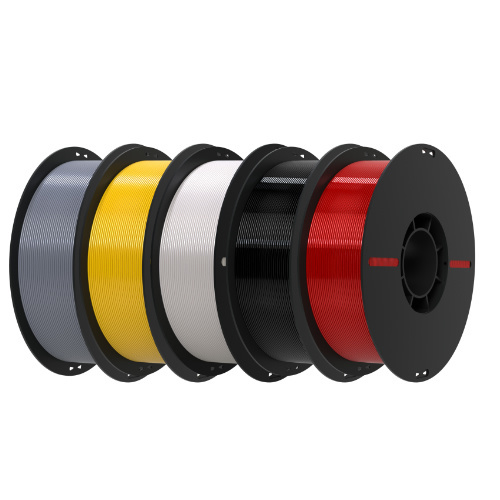

Sustainability is another critical consideration in today's manufacturing landscape, and 3D printing offers promising solutions. By using only the material necessary to create an object, waste is minimized. Additionally, many modern 3D printer machines are designed to work with biodegradable and recycled materials, making them an attractive option for environmentally conscious companies.

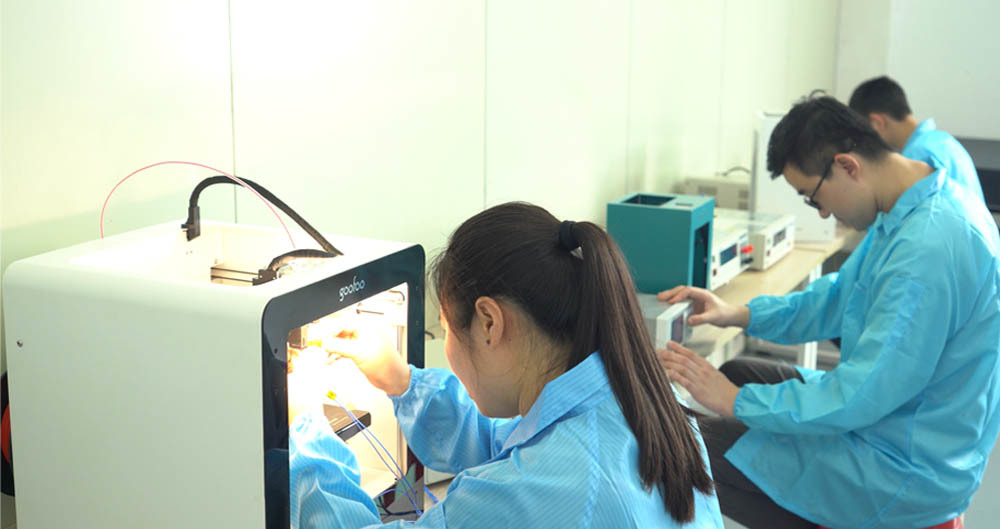

Despite these benefits, it's essential to recognize that 3D printer machines also come with challenges. The quality of the final product can depend heavily on the type of material used and the printer's settings. Furthermore, maintaining a consistent workflow can require a level of expertise that not all businesses possess, particularly smaller companies or startups.

In conclusion, 3D printer machines are at the forefront of a manufacturing revolution, offering unprecedented levels of customization, efficiency, and sustainability. As technology continues to advance, the potential applications for 3D printing will only expand, making it an essential area of focus for professionals across industries. Understanding the capabilities and limitations of these machines can empower businesses to harness their potential effectively, leading to innovative solutions and enhanced operational workflows.

One of the most significant advantages of 3D printer machines is their versatility. They can produce a vast array of items, from prototypes and spare parts to complex architectural models and consumer products. This flexibility makes them invaluable in various sectors, including automotive, aerospace, healthcare, and even fashion. For instance, in healthcare, 3D printers have been used to create custom prosthetics and dental implants tailored to the individual needs of patients, enhancing comfort and functionality.

Moreover, 3D printer machines facilitate rapid prototyping, allowing designers and engineers to iterate on their concepts much faster than traditional methods would allow. This speed can significantly reduce time-to-market for new products, giving companies a competitive edge. By quickly producing prototypes, teams can test functionality and design, gather feedback, and make necessary adjustments before committing to large-scale production.

Sustainability is another critical consideration in today's manufacturing landscape, and 3D printing offers promising solutions. By using only the material necessary to create an object, waste is minimized. Additionally, many modern 3D printer machines are designed to work with biodegradable and recycled materials, making them an attractive option for environmentally conscious companies.

Despite these benefits, it's essential to recognize that 3D printer machines also come with challenges. The quality of the final product can depend heavily on the type of material used and the printer's settings. Furthermore, maintaining a consistent workflow can require a level of expertise that not all businesses possess, particularly smaller companies or startups.

In conclusion, 3D printer machines are at the forefront of a manufacturing revolution, offering unprecedented levels of customization, efficiency, and sustainability. As technology continues to advance, the potential applications for 3D printing will only expand, making it an essential area of focus for professionals across industries. Understanding the capabilities and limitations of these machines can empower businesses to harness their potential effectively, leading to innovative solutions and enhanced operational workflows.

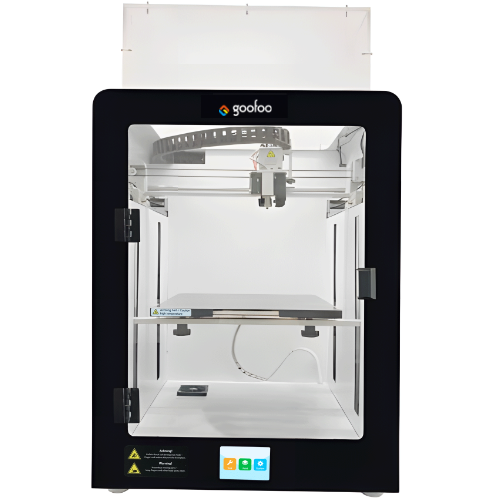

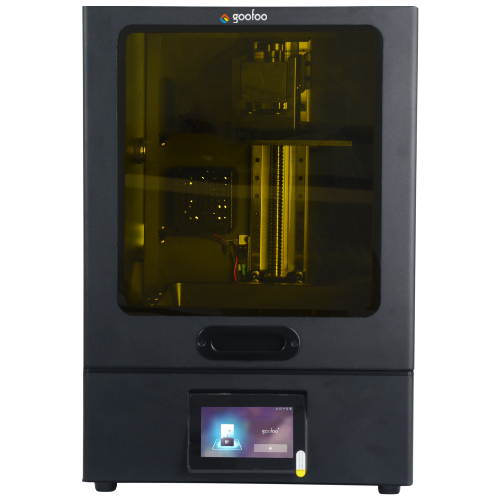

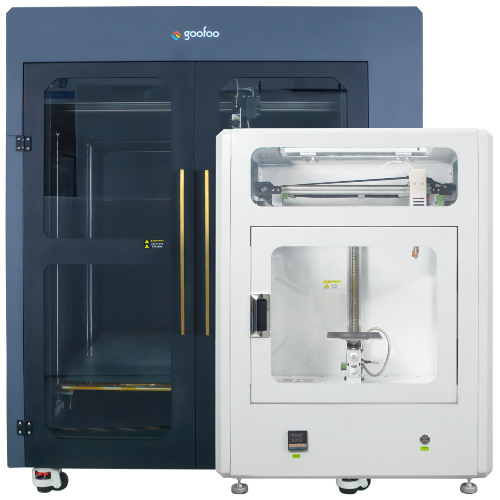

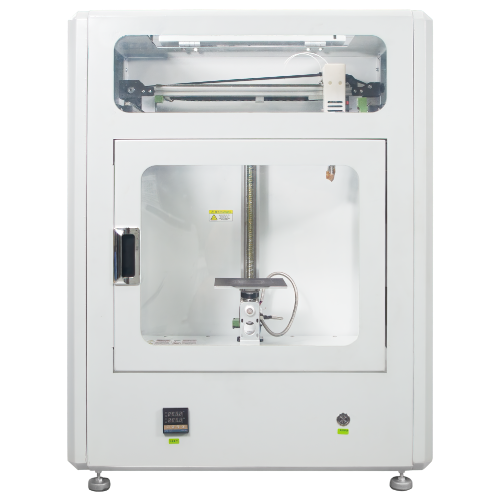

3d printer machine

Recommended News

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Skype / WhatsApp: +86 592-5713513 / +86-13860126490

No.88-3, North Tongji Road, Xike County, Tong'an District, Xiamen, Fujian China

Xiamen Goofoo Technology Co., Ltd. All Rights Reserved 闽ICP备2022008070号-1 SEO 300.cn

Phone:+0086 592-5713513

Address: No.88-3, North Tongji Road, Xike County, Tong’an District, Xiamen, Fujian China

Email: sales@goofoo3d.com

We will give you feedback in time