All Categories

Exploring the Advantages and Applications of 3D Printers with Resin

2025-10-31 11:50

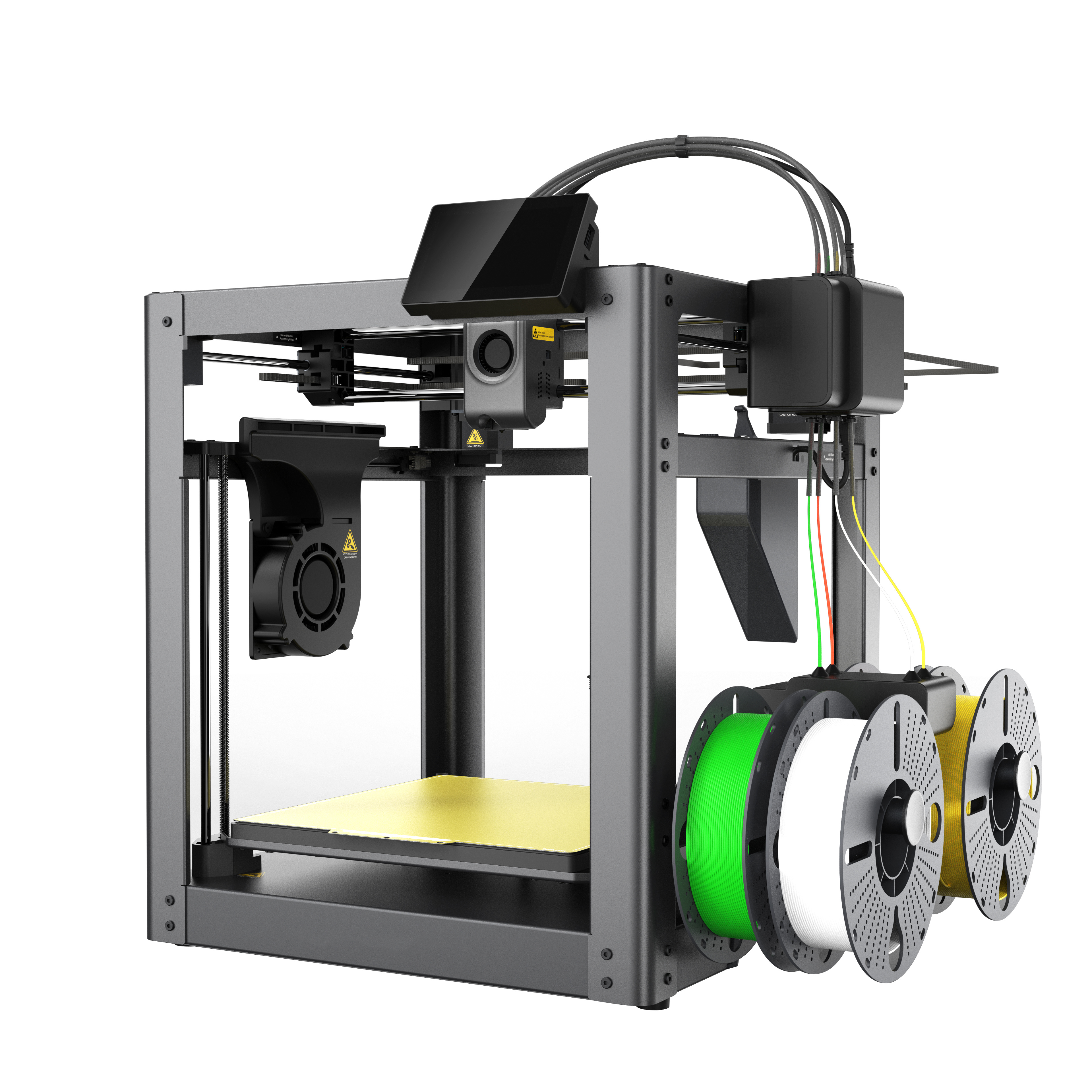

3D printers have revolutionized the manufacturing landscape, and among the various types available, resin-based 3D printers stand out for their precision and versatility. Unlike traditional filament printers, resin printers utilize a liquid photopolymer resin that hardens when exposed to a specific light source, typically UV light. This process, known as stereolithography (SLA), allows for incredibly detailed prints, making it an ideal choice for professionals in fields such as engineering, design, and prototyping.

One of the foremost advantages of a 3D printer with resin is the exceptional print quality it can achieve. The high resolution allows for intricate details and smooth surfaces, which are often necessary for applications like jewelry design, dental modeling, and miniatures for gaming. The layer thickness in resin printing can be considerably thinner than that of filament printing, resulting in finer details that can enhance the overall aesthetic and functional quality of the printed object.

Moreover, resin printers have a faster print speed than traditional methods when it comes to creating high-quality parts. While the initial setup may require careful calibration and a learning curve related to resin handling and post-processing, the output efficiency can be remarkable. For professionals looking to produce prototypes or models quickly, a 3D printer with resin may provide the swift turnaround necessary in a competitive market.

However, it's essential to consider the materials involved in resin printing. Resins can vary widely in terms of their properties, such as flexibility, durability, and temperature resistance. This variability allows users to choose a resin that perfectly fits their project requirements, whether that be for creating flexible prototypes or rigid components. Understanding the different types of resins available can help professionals select the right material for their specific needs.

Another critical aspect to consider is post-processing. After printing, resin parts often require cleaning and curing to achieve optimal strength and finish. This process may involve using isopropyl alcohol for cleaning and exposing the print to UV light for curing. While this adds additional steps to the workflow, the resulting quality often justifies the effort, making it a worthwhile consideration for serious projects.

In conclusion, a 3D printer with resin represents a significant technological advancement that offers numerous benefits for professionals in various industries. From exceptional detail and print quality to rapid production capabilities and material versatility, resin printers are poised to play a vital role in the future of digital manufacturing. By understanding the intricacies of this technology, professionals can harness its power to drive innovation and elevate their projects to new heights.

One of the foremost advantages of a 3D printer with resin is the exceptional print quality it can achieve. The high resolution allows for intricate details and smooth surfaces, which are often necessary for applications like jewelry design, dental modeling, and miniatures for gaming. The layer thickness in resin printing can be considerably thinner than that of filament printing, resulting in finer details that can enhance the overall aesthetic and functional quality of the printed object.

Moreover, resin printers have a faster print speed than traditional methods when it comes to creating high-quality parts. While the initial setup may require careful calibration and a learning curve related to resin handling and post-processing, the output efficiency can be remarkable. For professionals looking to produce prototypes or models quickly, a 3D printer with resin may provide the swift turnaround necessary in a competitive market.

However, it's essential to consider the materials involved in resin printing. Resins can vary widely in terms of their properties, such as flexibility, durability, and temperature resistance. This variability allows users to choose a resin that perfectly fits their project requirements, whether that be for creating flexible prototypes or rigid components. Understanding the different types of resins available can help professionals select the right material for their specific needs.

Another critical aspect to consider is post-processing. After printing, resin parts often require cleaning and curing to achieve optimal strength and finish. This process may involve using isopropyl alcohol for cleaning and exposing the print to UV light for curing. While this adds additional steps to the workflow, the resulting quality often justifies the effort, making it a worthwhile consideration for serious projects.

In conclusion, a 3D printer with resin represents a significant technological advancement that offers numerous benefits for professionals in various industries. From exceptional detail and print quality to rapid production capabilities and material versatility, resin printers are poised to play a vital role in the future of digital manufacturing. By understanding the intricacies of this technology, professionals can harness its power to drive innovation and elevate their projects to new heights.

3d printer with resin

Recommended News

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Skype / WhatsApp: +86 592-5713513 / +86-13860126490

No.88-3, North Tongji Road, Xike County, Tong'an District, Xiamen, Fujian China

Xiamen Goofoo Technology Co., Ltd. All Rights Reserved 闽ICP备2022008070号-1 SEO 300.cn

Phone:+0086 592-5713513

Address: No.88-3, North Tongji Road, Xike County, Tong’an District, Xiamen, Fujian China

Email: sales@goofoo3d.com

We will give you feedback in time