All Categories

Enhance Your Design Skills with Cutting-Edge 3D Printer Models

2025-10-27 12:30

Enhance Your Design Skills with Cutting-Edge 3D Printer Models

Table of Contents

- Introduction to 3D Printing Technology

- Benefits of Using Cutting-Edge 3D Printers

- Types of 3D Printers for Designers

- Key Features to Look for in 3D Printers

- Top Cutting-Edge 3D Printer Models

- Tips for Enhancing Your Design Skills with 3D Printing

- Case Studies: Success Stories of Designers

- Future Trends in 3D Printing Technology

- Frequently Asked Questions

- Conclusion

Introduction to 3D Printing Technology

In recent years, **3D printing** has revolutionized the way we approach design and manufacturing. This technology allows designers and engineers to create three-dimensional objects from digital models, empowering them to bring their creative visions to life like never before. The integration of **cutting-edge 3D printer models** has made it possible to produce intricate designs with exceptional accuracy and efficiency. From prototyping to final products, these printers have opened up new avenues for innovation across various industries.

Benefits of Using Cutting-Edge 3D Printers

The adoption of advanced 3D printing technology offers numerous advantages for designers. Here are some key benefits:

1. Enhanced Creativity

With **advanced 3D printers**, designers can create complex geometries and intricate details that were previously unattainable using traditional manufacturing techniques. This freedom encourages experimentation and fosters innovation.

2. Rapid Prototyping

Cutting-edge 3D printers enable rapid prototyping, allowing designers to quickly turn their concepts into tangible products. This iterative process minimizes development time and costs, facilitating a more agile workflow.

3. Customization and Personalization

Modern 3D printers allow for high levels of customization, enabling designers to tailor their products to meet specific customer needs. This capability is particularly beneficial in industries like fashion, jewelry, and healthcare.

4. Cost-Effectiveness

While the initial investment in a high-quality 3D printer may be significant, the long-term savings on materials, labor, and production time can offset these costs. The ability to produce items on-demand reduces waste and inventory expenses.

5. Access to a Wide Range of Materials

Cutting-edge 3D printers are compatible with various materials, including plastics, metals, and even ceramics. This versatility expands the range of applications for designers, allowing them to explore new possibilities in their work.

Types of 3D Printers for Designers

Understanding the different types of 3D printers available is crucial for selecting the right model for your design needs. Here are the most common types:

1. Fused Deposition Modeling (FDM)

FDM printers work by melting layers of thermoplastic filament and depositing them layer by layer to create the desired object. This type is popular among hobbyists and entry-level designers due to its affordability and ease of use.

2. Stereolithography (SLA)

SLA printers utilize a UV light source to cure liquid resin into solid objects. This technology is known for its high precision and smooth finish, making it ideal for detailed designs and prototypes.

3. Selective Laser Sintering (SLS)

SLS printers employ a laser to fuse powdered material into solid structures. This method allows for the creation of complex parts without the need for support structures, making it suitable for industrial applications.

4. Digital Light Processing (DLP)

Similar to SLA, DLP printers use a digital light projector to cure resin. DLP models are known for their speed and accuracy, making them a preferred choice for jewelry and dental applications.

Key Features to Look for in 3D Printers

When selecting a cutting-edge 3D printer, consider the following features to ensure it meets your design requirements:

1. Build Volume

The build volume determines the maximum size of objects you can print. For designers working on larger projects, opting for a printer with a generous build volume is essential.

2. Print Resolution

Print resolution directly affects the detail and quality of your finished product. Higher resolution printers produce smoother surfaces and finer details, which is crucial for intricate designs.

3. Material Compatibility

Ensure the printer supports a variety of materials, as this flexibility will allow you to explore different design possibilities and applications.

4. User-Friendly Software

A user-friendly interface and robust software options are vital for effective design manipulation and printer operation. Look for printers that offer intuitive software solutions that cater to both beginners and advanced users.

5. Reliability and Support

Consider the manufacturer’s reputation for reliability and customer support. A trustworthy brand will provide assistance and resources to help you maximize your printer's capabilities.

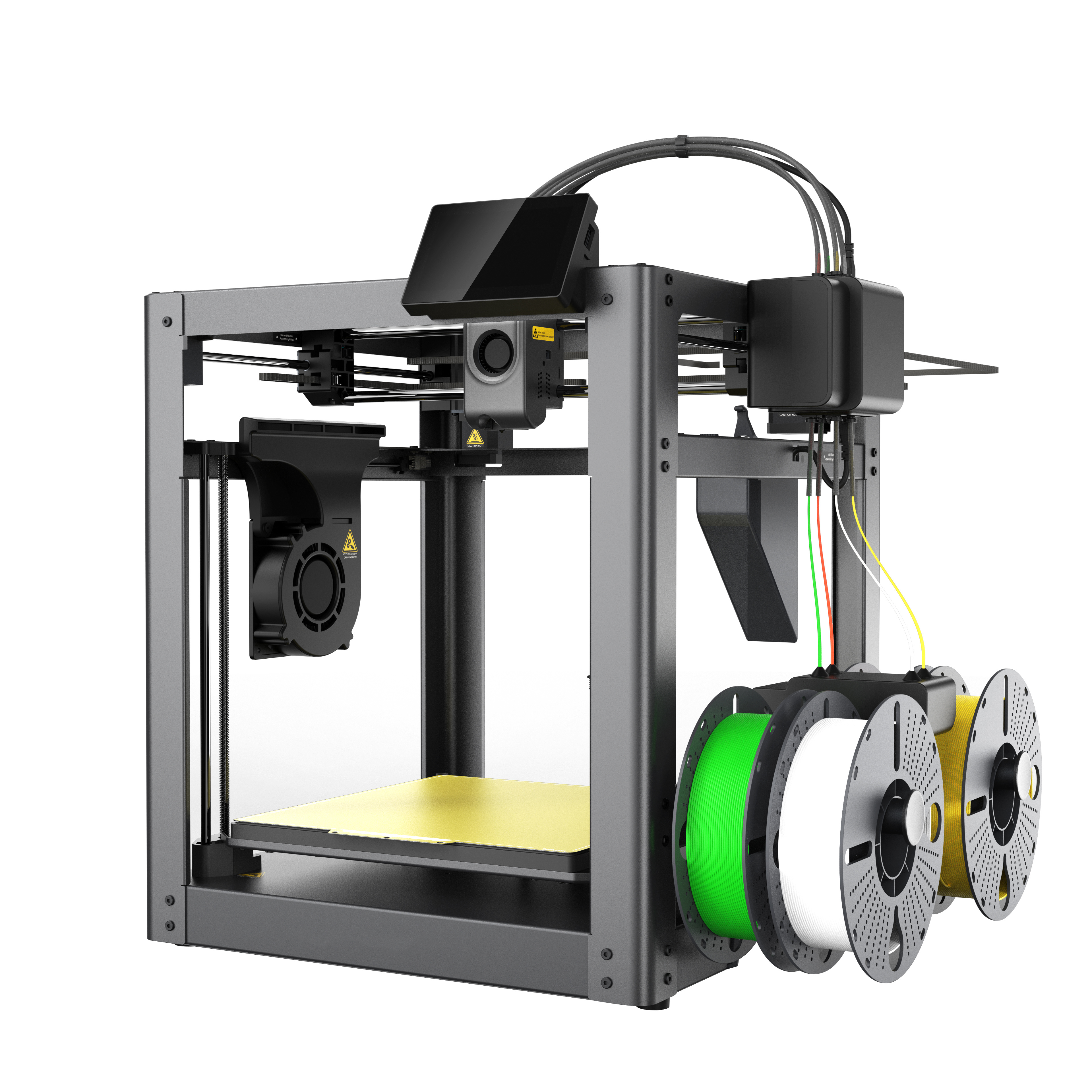

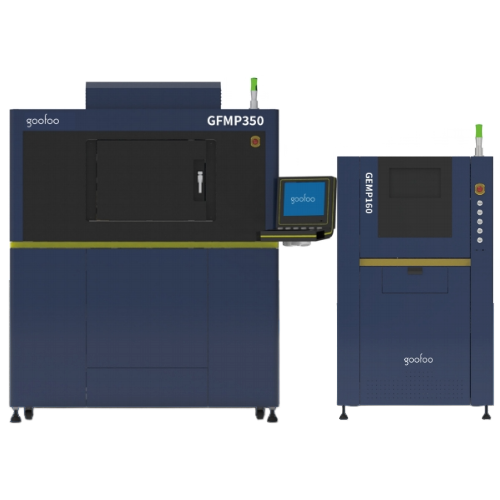

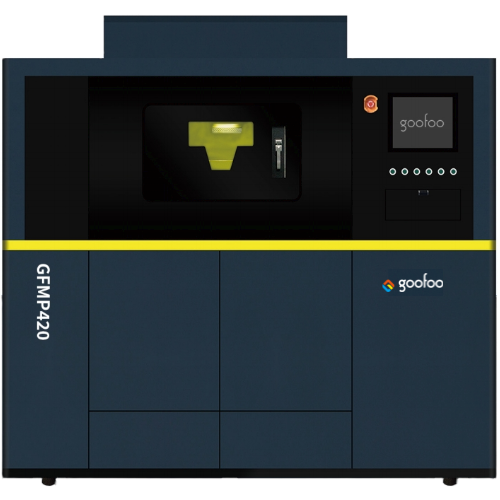

Top Cutting-Edge 3D Printer Models

When it comes to choosing a 3D printer, several models stand out for their cutting-edge technology and performance. Here are some top contenders:

1. Ultimaker S3

The Ultimaker S3 is known for its precision and versatility. With a build volume of 230 x 190 x 200 mm and compatibility with various materials, this printer is ideal for both beginners and experienced designers.

2. Formlabs Form 3

The Form 3 is a leading SLA printer that offers high-quality prints with incredible detail. Its advanced resin technology allows for a wide range of applications, from dental models to intricate prototypes.

3. Prusa i3 MK3S+

This FDM printer is popular for its reliability and high-quality prints. It features a large build volume, automatic bed leveling, and a user-friendly interface, making it a great choice for hobbyists and professionals alike.

4. Raise3D Pro2

The Raise3D Pro2 is a robust dual-extruder printer that excels in creating complex designs with multiple materials. Its large build volume and support for a wide range of filaments make it suitable for industrial applications.

5. Anycubic Photon Mono X

For those seeking a budget-friendly SLA printer, the Anycubic Photon Mono X offers an impressive print quality and speed. It’s perfect for detailed miniatures and prototypes without breaking the bank.

Tips for Enhancing Your Design Skills with 3D Printing

To make the most of your 3D printing experience, consider these tips for enhancing your design skills:

1. Familiarize Yourself with Software

Invest time in learning 3D modeling software like Fusion 360, Blender, or Tinkercad. Mastering these tools will allow you to create more complex and refined designs.

2. Experiment with Different Materials

Don’t hesitate to explore various materials to find those that best suit your designs. Each material offers unique properties, allowing you to tailor your projects accordingly.

3. Join Online Communities

Engage with online forums and communities focused on 3D printing and design. Networking with other designers can provide valuable insights, tips, and feedback on your work.

4. Document Your Projects

Keep a record of your design process, including successes and challenges. This documentation will help you reflect on your growth and improve your skills over time.

5. Attend Workshops and Tutorials

Participating in workshops or online tutorials can provide hands-on experience, helping you refine your techniques and learn new skills from industry experts.

Case Studies: Success Stories of Designers

Exploring real-life examples of designers who have successfully integrated 3D printing into their workflows can provide inspiration and practical insights.

1. Product Design: Rethinking Prototyping

A product designer utilized SLA technology to develop a line of custom kitchen gadgets. By leveraging rapid prototyping, they reduced their design cycle from months to weeks, leading to quicker time-to-market and increased customer satisfaction.

2. Fashion Innovation: Custom Accessories

A fashion designer embraced 3D printing to create intricate jewelry pieces. This approach allowed them to experiment with unconventional designs and materials, resulting in unique products that captivated their audience.

3. Medical Applications: Prosthetics Development

A team of biomedical engineers used SLS 3D printing to develop custom prosthetics tailored to individual patients. The ability to create lightweight, durable, and precisely fitting prosthetics enhanced the quality of life for many users.

Future Trends in 3D Printing Technology

As technology continues to advance, the future of 3D printing holds exciting possibilities for designers. Some emerging trends include:

1. Bioprinting

The ability to print living tissues and organs is on the horizon, promising revolutionary advancements in medicine and healthcare.

2. Sustainable Materials

As the demand for eco-friendly solutions increases, the development of sustainable 3D printing materials will likely expand, promoting environmentally responsible design practices.

3. AI Integration

Artificial intelligence is poised to enhance the design process by automating certain tasks, optimizing designs for performance, and even generating creative solutions.

4. Hybrid Manufacturing

The combination of 3D printing with traditional manufacturing methods will allow for more complex products and improved efficiency, pushing the boundaries of what is possible in design.

Frequently Asked Questions

1. What is the best 3D printer for beginners?

For beginners, the Prusa i3 MK3S+ or the Ultimaker S3 are great options due to their user-friendly interfaces and extensive support resources.

2. Can I use my 3D printer for professional work?

Absolutely! Many cutting-edge models are designed for professional use, providing high precision and reliability suitable for various industries.

3. How much does a quality 3D printer cost?

The cost of quality 3D printers can range from a few hundred to several thousand dollars, depending on the features and capabilities.

4. What materials can I use with 3D printers?

Most modern 3D printers can work with a variety of materials, including thermoplastics, resins, metals, and even ceramics.

5. How do I maintain my 3D printer?

Regular maintenance includes cleaning the print bed, checking the nozzle for clogs, and ensuring that the printer's software is up to date. Following the manufacturer's guidelines will help keep your printer in top condition.

Conclusion

Cutting-edge 3D printer models have transformed the design landscape, offering unprecedented opportunities for creativity and innovation. By embracing this technology, designers can enhance their skills, streamline their workflows, and produce high-quality products that stand out in the market. As advancements continue to unfold, staying informed and adaptable will be crucial in leveraging the full potential of 3D printing in design. Join us in exploring this exciting frontier and unlock new dimensions of creativity in your projects.

3d printer models

Recommended News

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Skype / WhatsApp: +86 592-5713513 / +86-13860126490

No.88-3, North Tongji Road, Xike County, Tong'an District, Xiamen, Fujian China

Xiamen Goofoo Technology Co., Ltd. All Rights Reserved 闽ICP备2022008070号-1 SEO 300.cn

Phone:+0086 592-5713513

Address: No.88-3, North Tongji Road, Xike County, Tong’an District, Xiamen, Fujian China

Email: sales@goofoo3d.com

We will give you feedback in time