All Categories

The Ultimate Guide to FDM 3D Printers: Unlocking the Potential of Additive Manufacturing

2025-09-21 11:20

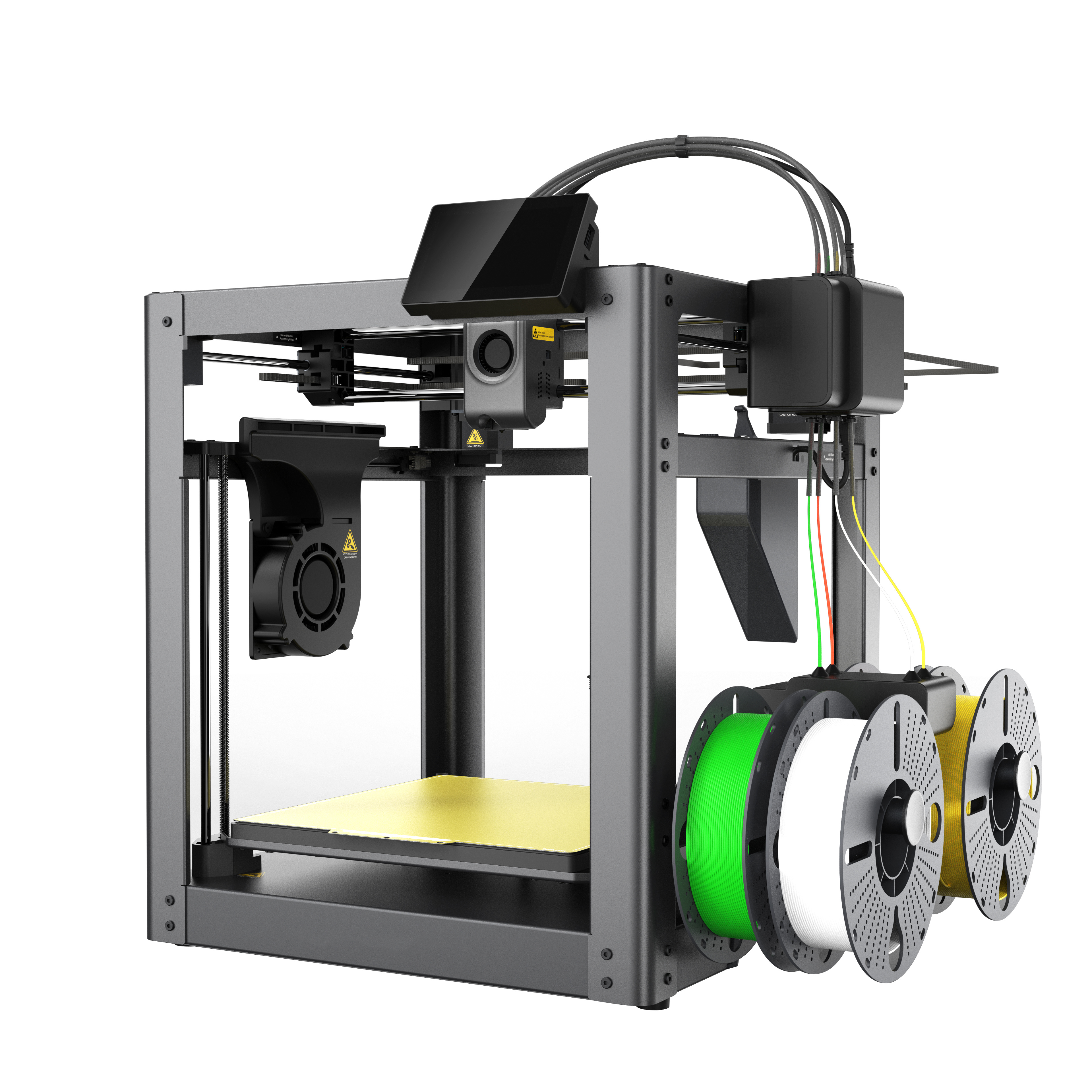

Fused Deposition Modeling (FDM) is a widely used 3D printing technology that has revolutionized the way we create prototypes and end-use parts. This method involves depositing melted thermoplastic material layer by layer to build three-dimensional objects from a digital file. As a professional in the computer and digital products industry, understanding FDM 3D printers can greatly enhance your project outcomes and innovation capabilities.

One of the primary advantages of FDM 3D printing is its accessibility and affordability. FDM printers are commonly available in a variety of price ranges, making them suitable for both small businesses and large enterprises. Moreover, the materials used in FDM printing, such as PLA and ABS, are relatively inexpensive and widely available, which significantly lowers the cost of prototyping and production.

Another notable benefit of FDM technology is its versatility. FDM printers can produce a wide range of geometries and designs, allowing for the creation of complex structures that would be challenging or impossible to manufacture using traditional methods. This capability makes FDM particularly appealing for industries such as engineering, architecture, and product design, where prototyping is essential for testing concepts and functionality.

However, there are important considerations to keep in mind when utilizing FDM 3D printers. Print quality can vary depending on multiple factors, including layer height, feed rate, and print speed. Professionals must also be aware of the importance of proper calibration and maintenance of the printer to ensure optimal performance and results. Additionally, cooling and adhesion during the printing process are crucial factors that can influence the success of a print job.

FDM 3D printers have numerous applications across various sectors. In prototyping, they allow for rapid iteration and testing of designs, significantly shortening development cycles. In manufacturing, FDM can be used for creating jigs, fixtures, or even end-use parts, streamlining production processes. Furthermore, the technology is gaining traction in educational settings, where it serves as a valuable tool for teaching students about design, engineering principles, and innovation.

In summary, FDM 3D printers are an essential tool for professionals in the computer and digital products industry. Their cost-effectiveness, versatility, and ability to produce complex geometries make them an attractive option for a wide range of applications. By understanding the principles, advantages, and considerations of FDM technology, you can harness its potential to drive innovation and efficiency in your projects. Embrace the future of manufacturing and elevate your work with the capabilities that FDM 3D printers offer.

One of the primary advantages of FDM 3D printing is its accessibility and affordability. FDM printers are commonly available in a variety of price ranges, making them suitable for both small businesses and large enterprises. Moreover, the materials used in FDM printing, such as PLA and ABS, are relatively inexpensive and widely available, which significantly lowers the cost of prototyping and production.

Another notable benefit of FDM technology is its versatility. FDM printers can produce a wide range of geometries and designs, allowing for the creation of complex structures that would be challenging or impossible to manufacture using traditional methods. This capability makes FDM particularly appealing for industries such as engineering, architecture, and product design, where prototyping is essential for testing concepts and functionality.

However, there are important considerations to keep in mind when utilizing FDM 3D printers. Print quality can vary depending on multiple factors, including layer height, feed rate, and print speed. Professionals must also be aware of the importance of proper calibration and maintenance of the printer to ensure optimal performance and results. Additionally, cooling and adhesion during the printing process are crucial factors that can influence the success of a print job.

FDM 3D printers have numerous applications across various sectors. In prototyping, they allow for rapid iteration and testing of designs, significantly shortening development cycles. In manufacturing, FDM can be used for creating jigs, fixtures, or even end-use parts, streamlining production processes. Furthermore, the technology is gaining traction in educational settings, where it serves as a valuable tool for teaching students about design, engineering principles, and innovation.

In summary, FDM 3D printers are an essential tool for professionals in the computer and digital products industry. Their cost-effectiveness, versatility, and ability to produce complex geometries make them an attractive option for a wide range of applications. By understanding the principles, advantages, and considerations of FDM technology, you can harness its potential to drive innovation and efficiency in your projects. Embrace the future of manufacturing and elevate your work with the capabilities that FDM 3D printers offer.

3d printer fdm

Recommended News

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Skype / WhatsApp: +86 592-5713513 / +86-13860126490

No.88-3, North Tongji Road, Xike County, Tong'an District, Xiamen, Fujian China

Xiamen Goofoo Technology Co., Ltd. All Rights Reserved 闽ICP备2022008070号-1 SEO 300.cn

Phone:+0086 592-5713513

Address: No.88-3, North Tongji Road, Xike County, Tong’an District, Xiamen, Fujian China

Email: sales@goofoo3d.com

We will give you feedback in time