All Categories

Innovation Unleashed: The Evolution of 3D Printer Design Technology

2025-06-29 11:00

Innovation Unleashed: The Evolution of 3D Printer Design Technology

Table of Contents

- 1. Introduction to 3D Printing Technology

- 2. The Historical Development of 3D Printing

- 3. Key Technologies Behind 3D Printing

- 4. The Impact of 3D Printing Across Industries

- 5. The Future of 3D Printer Design Technology

- 6. Challenges and Limitations of 3D Printing

- 7. Innovations in 3D Printing Materials

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to 3D Printing Technology

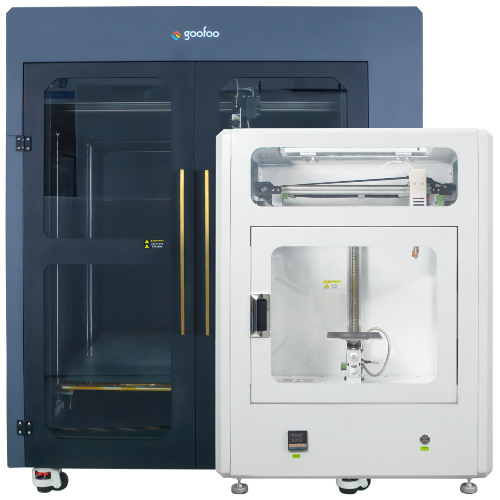

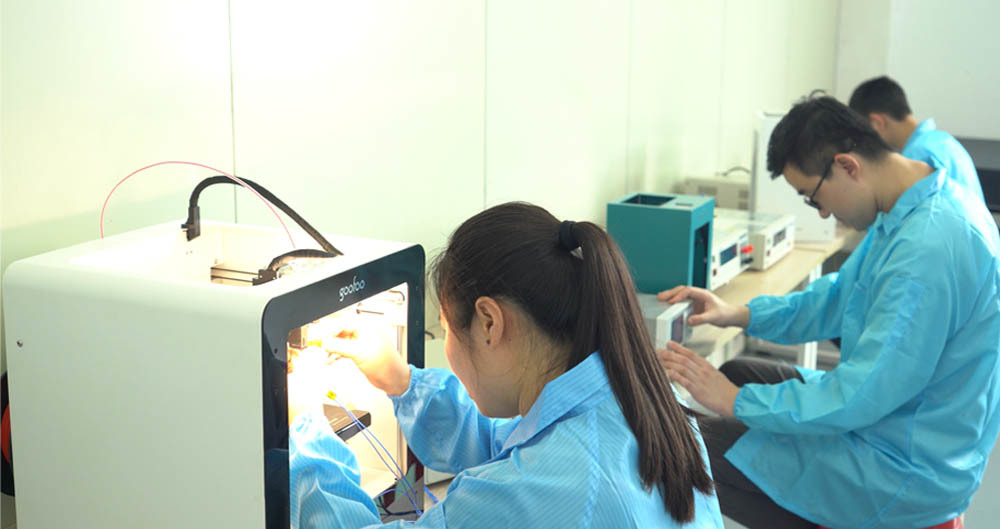

3D printing technology, often referred to as additive manufacturing, has revolutionized the way we create and design products. By building objects layer by layer from digital models, this innovative technology allows for unprecedented flexibility and creativity. Industries ranging from healthcare to aerospace are leveraging 3D printing to enhance production efficiency and reduce costs. In this article, we will explore the evolution of 3D printing design technology, its applications, and its potential future developments.

2. The Historical Development of 3D Printing

The roots of 3D printing can be traced back to the early 1980s when Chuck Hull invented stereolithography (SLA), the first 3D printing technology. This groundbreaking advancement laid the foundation for subsequent developments. Over the decades, various technologies emerged, including fused deposition modeling (FDM) in the early 1990s, selective laser sintering (SLS), and digital light processing (DLP).

Each of these technologies contributed unique capabilities to 3D printing, shaping the industry we know today. The evolution from simple prototypes to complex, functional parts exemplifies the rapid advancements in 3D printer design technology.

3. Key Technologies Behind 3D Printing

Understanding the different technologies that drive 3D printing is essential for grasping its full potential. Below are some of the key technologies that have shaped the evolution of 3D printing:

3.1 Stereolithography (SLA)

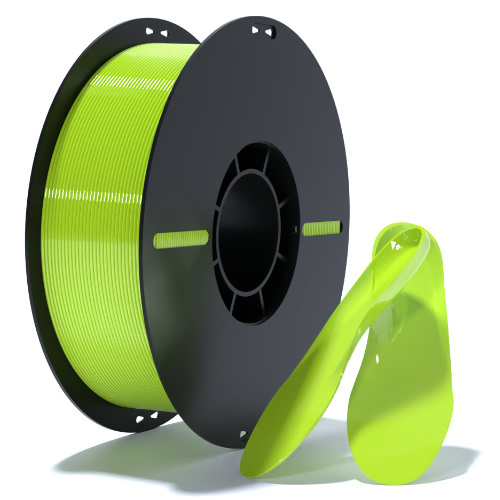

SLA uses ultraviolet light to cure liquid resin into hardened plastic. This technology is known for producing high-resolution models with smooth surfaces, making it ideal for detailed prototypes and intricate designs.

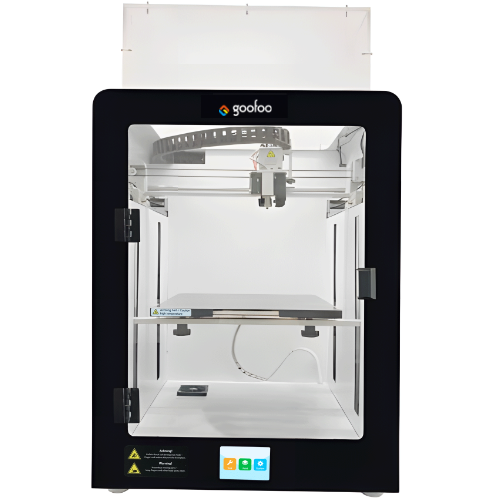

3.2 Fused Deposition Modeling (FDM)

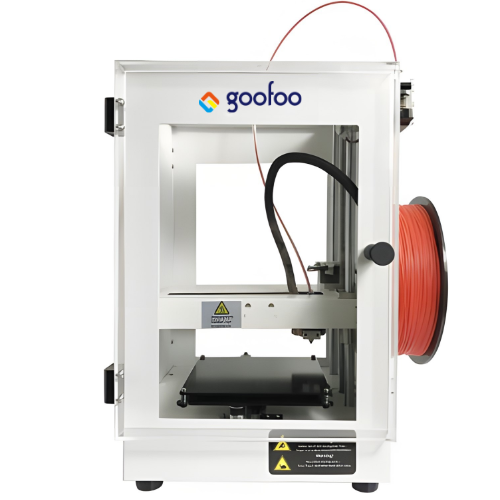

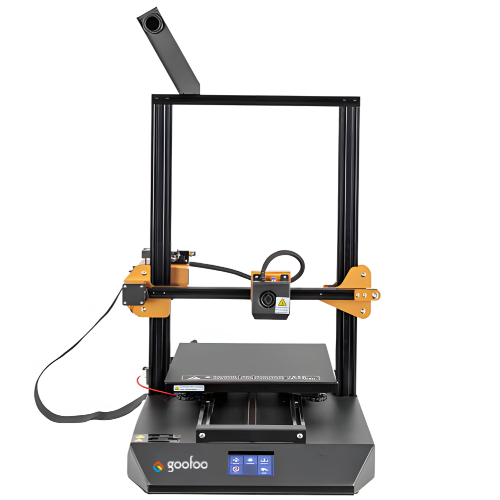

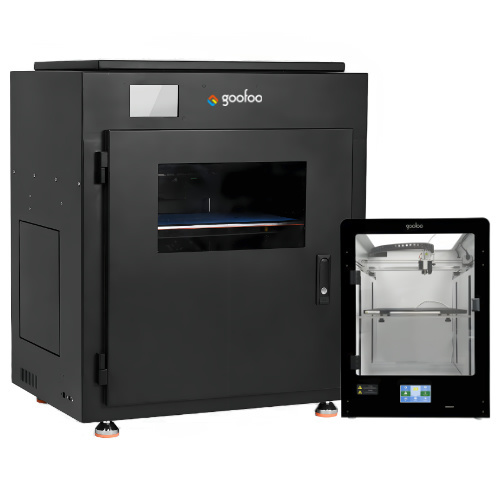

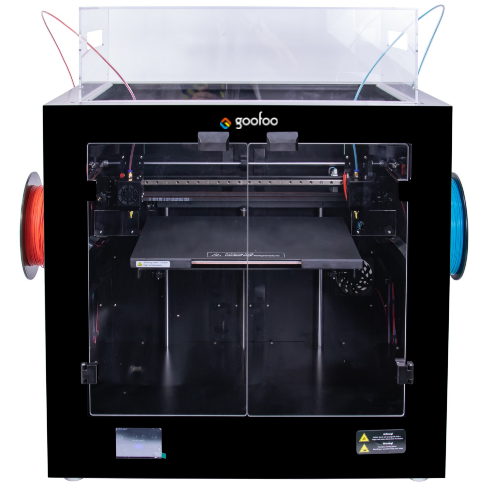

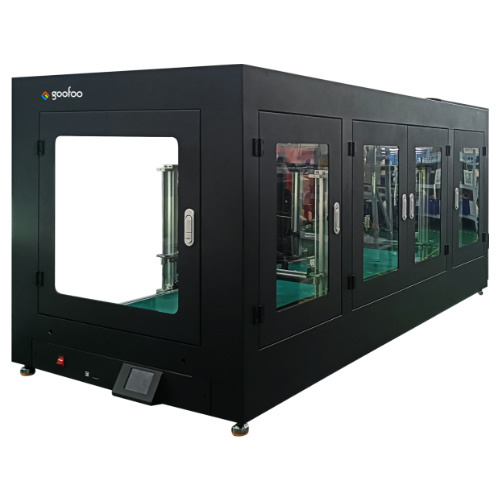

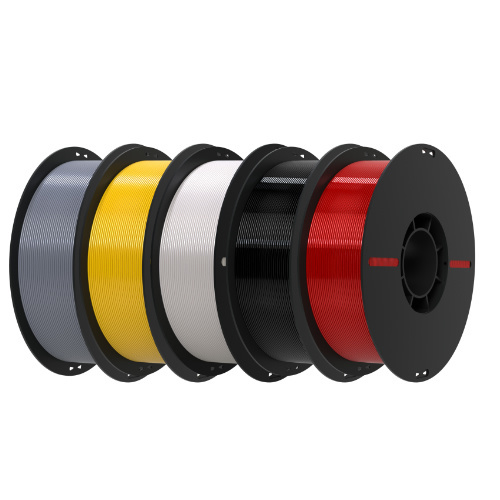

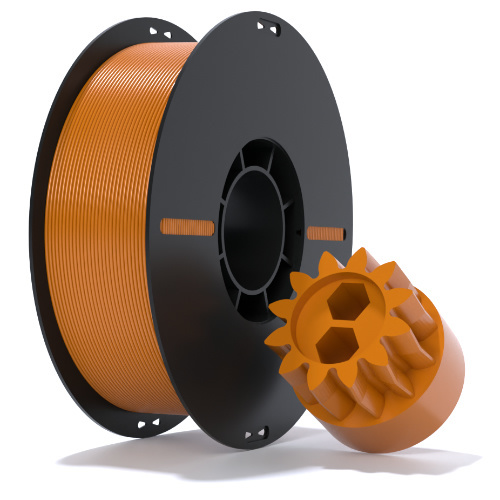

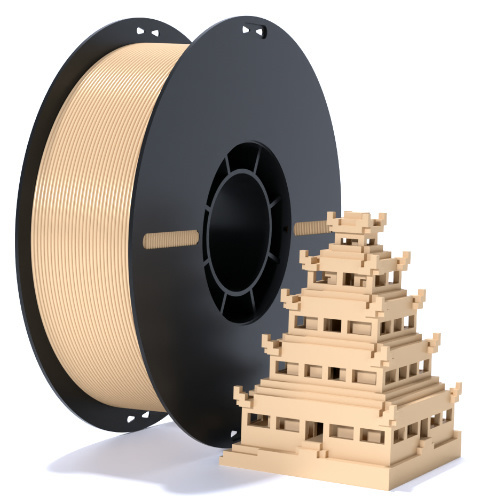

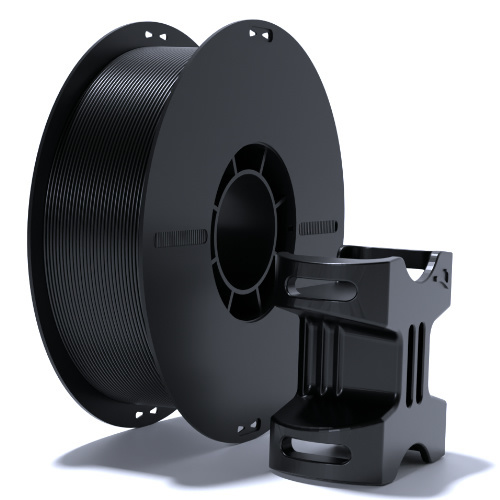

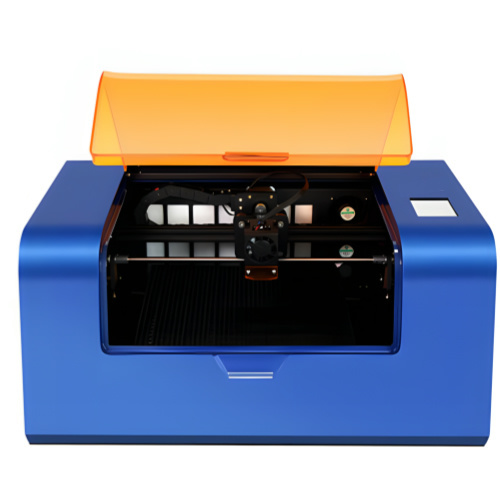

FDM is one of the most widely used 3D printing technologies. It works by melting thermoplastic filament and extruding it layer by layer to create a 3D object. FDM printers are cost-effective and user-friendly, making them popular among hobbyists and professionals alike.

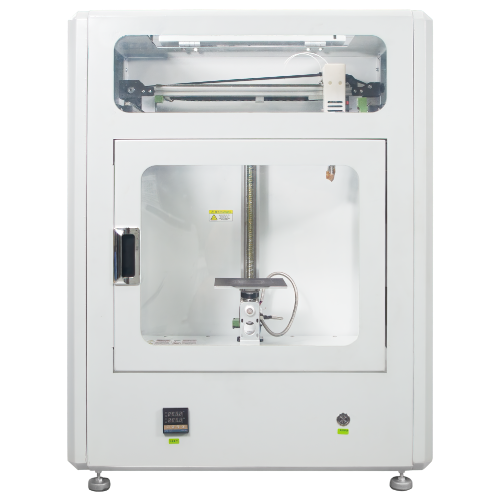

3.3 Selective Laser Sintering (SLS)

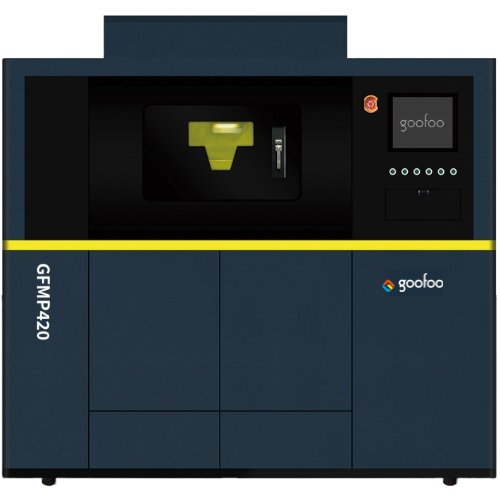

SLS employs a laser to sinter powdered material, bonding it together to create a solid structure. This technology allows for the creation of complex geometries and is commonly used in industrial applications.

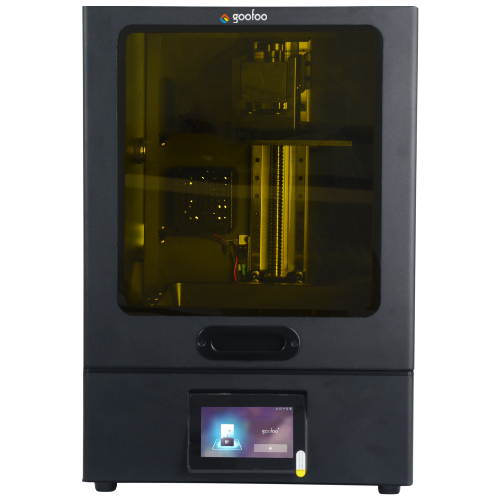

3.4 Digital Light Processing (DLP)

DLP uses a digital light projector to flash a single image of each layer across the resin, curing it rapidly. This method is known for its speed and accuracy, making it suitable for high-volume production.

4. The Impact of 3D Printing Across Industries

The versatility of 3D printing has led to its adoption across various sectors, each benefiting from its unique capabilities.

4.1 Healthcare Innovations

In healthcare, 3D printing is used to create custom prosthetics, implants, and even bioprinted tissues. This technology allows for personalized medical solutions tailored to individual patients, enhancing treatment outcomes.

4.2 Aerospace Advancements

The aerospace industry utilizes 3D printing to manufacture lightweight components that contribute to fuel efficiency. Moreover, the ability to produce complex parts reduces waste and lowers production costs.

4.3 Automotive Design

Automakers are embracing 3D printing for rapid prototyping and producing end-use parts. This approach accelerates the design process and enables manufacturers to respond quickly to market demands.

4.4 Consumer Products

In consumer goods, 3D printing allows for customization and personalization. From unique jewelry to tailored home decor, consumers can bring their creative visions to life with ease.

5. The Future of 3D Printer Design Technology

The future of 3D printing holds immense promise. As technology continues to advance, we can expect faster printing speeds, improved material properties, and greater accessibility.

5.1 Integration with AI and Machine Learning

The incorporation of artificial intelligence and machine learning into 3D printing processes will optimize design and production, enhancing efficiency and reducing errors.

5.2 Sustainable Practices

With growing environmental concerns, the future of 3D printing may focus on sustainable materials and processes. Innovations in biodegradable filaments and recycling technologies will pave the way for eco-friendly manufacturing.

5.3 Expansion of Bioprinting

Bioprinting, the process of creating living tissues and organs using 3D printing, represents a frontier with the potential to revolutionize healthcare. Ongoing research aims to develop functional organs for transplantation, addressing critical shortages.

6. Challenges and Limitations of 3D Printing

While 3D printing presents numerous advantages, it also faces challenges that must be addressed for widespread adoption.

6.1 Material Limitations

The variety of materials available for 3D printing is still somewhat limited compared to traditional manufacturing methods. Expanding the range of materials will enhance the applications and capabilities of 3D printing.

6.2 Production Speed

Despite advancements, many 3D printers still operate at slower speeds than traditional manufacturing processes, which can hinder scalability for large production runs.

6.3 Intellectual Property Issues

The ease of replicating designs raises concerns about intellectual property rights. Establishing clear regulations will be crucial as the industry evolves.

7. Innovations in 3D Printing Materials

The evolution of 3D printing technology is closely tied to advancements in materials science. Innovative materials are expanding the possibilities of what can be created.

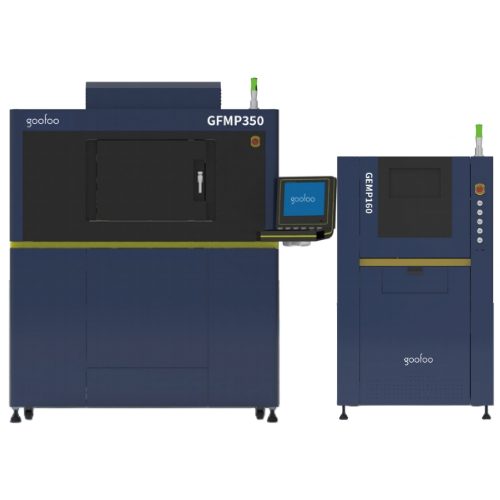

7.1 Metal 3D Printing

Metal 3D printing technologies, such as direct metal laser sintering (DMLS), are gaining traction in industrial applications. These advanced methods allow for the creation of complex metal components with enhanced performance characteristics.

7.2 Biodegradable Filaments

The development of biodegradable filaments addresses environmental concerns associated with plastic waste. These sustainable materials are creating opportunities for eco-conscious consumers and manufacturers.

7.3 Composite Materials

Composite materials, which combine different substances to create enhanced properties, are becoming increasingly popular in 3D printing. These materials offer strength, durability, and a lightweight structure, making them ideal for demanding applications.

8. Frequently Asked Questions

8.1 What is 3D printing?

3D printing is an additive manufacturing process that creates three-dimensional objects by layering materials based on digital designs.

8.2 What are the main types of 3D printing technologies?

The main types include Stereolithography (SLA), Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Digital Light Processing (DLP).

8.3 How is 3D printing used in healthcare?

3D printing is used to create custom prosthetics, implants, and even bioprinted tissues, allowing for personalized medical solutions.

8.4 What materials can be used in 3D printing?

A wide range of materials can be used, including plastics, metals, ceramics, and biodegradable filaments.

8.5 What challenges does 3D printing face?

Challenges include material limitations, production speed, and intellectual property issues.

9. Conclusion

The evolution of 3D printer design technology is a testament to human innovation and creativity. As we have explored, this technology has not only transformed manufacturing processes but has also opened up new possibilities across various industries. Looking ahead, the integration of advanced materials, AI, and sustainable practices will continue to drive the evolution of 3D printing. Embracing these changes will empower businesses and individuals to harness the full potential of 3D printing, ultimately shaping the future of design and production.

3d printer design

Recommended News

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Skype / WhatsApp: +86 592-5713513 / +86-13860126490

No.88-3, North Tongji Road, Xike County, Tong'an District, Xiamen, Fujian China

Xiamen Goofoo Technology Co., Ltd. All Rights Reserved 闽ICP备2022008070号-1 SEO 300.cn

Phone:+0086 592-5713513

Address: No.88-3, North Tongji Road, Xike County, Tong’an District, Xiamen, Fujian China

Email: sales@goofoo3d.com

We will give you feedback in time