All Categories

Understanding SLA 3D Printers: The Future of Precision Printing

2025-06-25 11:20

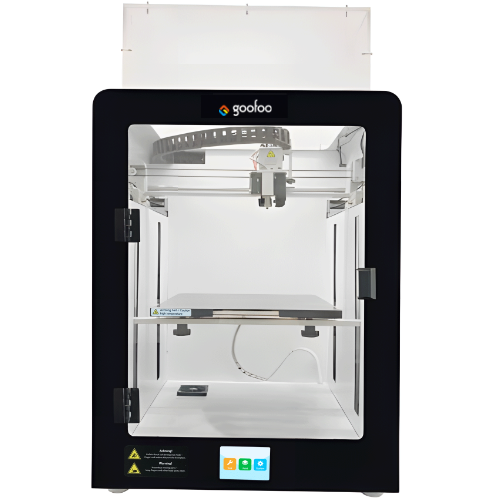

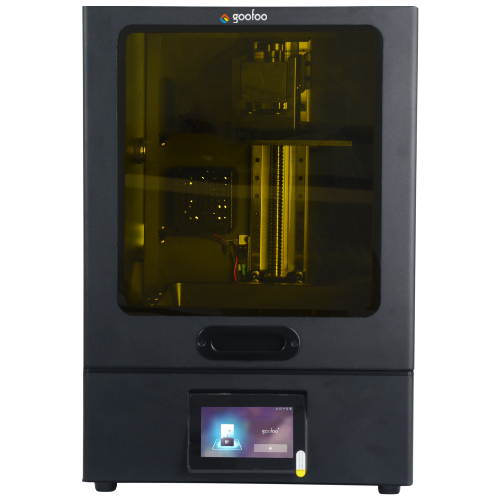

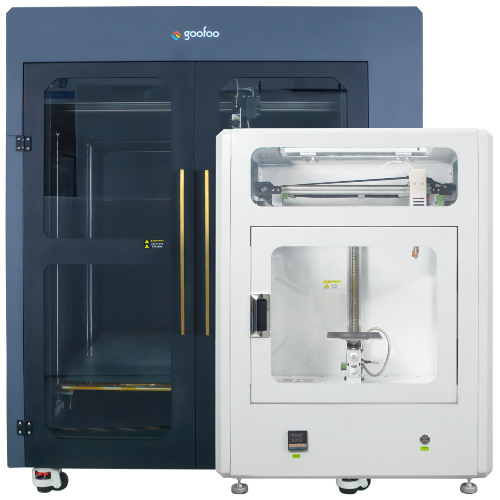

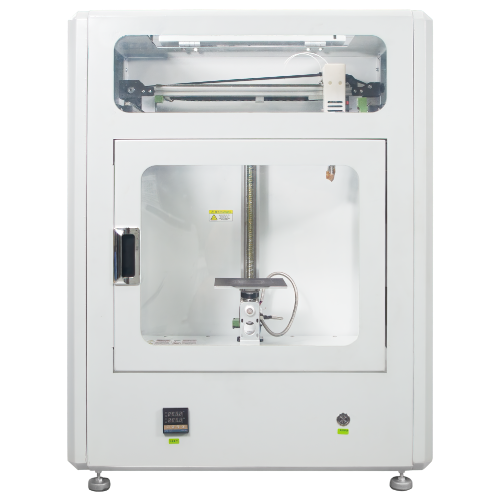

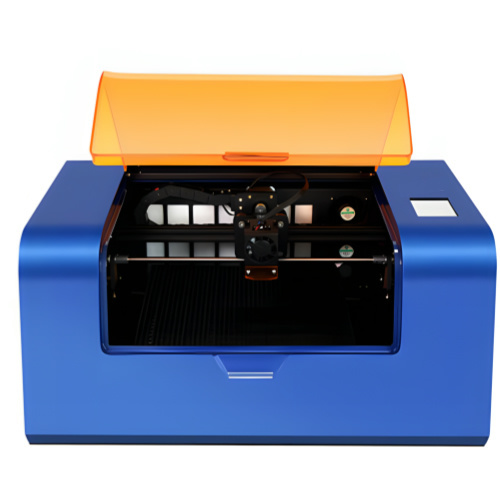

SLA 3D printers, short for Stereolithography Apparatus, represent one of the most advanced forms of 3D printing technology available today. Unlike traditional FDM printers that utilize filament, SLA printers use a laser to cure liquid resin layer by layer, resulting in highly detailed and smooth finishes. This process is particularly beneficial for industries that require precise prototypes, intricate designs, and high-quality models.

One of the standout features of SLA 3D printers is their ability to produce parts with fine details that are often unattainable with other 3D printing methods. This makes SLA ideal for applications in jewelry making, dental models, and intricate engineering components. The level of accuracy provided by SLA technology ensures that even the most complex geometries can be printed with exceptional fidelity, which is critical for industries where precision is paramount.

In addition to their high detail resolution, SLA printers also offer a variety of resin options that can cater to specific needs. From tough, durable resins suitable for functional testing to flexible materials that can simulate rubber-like properties, the versatility of SLA resins helps designers and engineers innovate without limitations. Furthermore, the post-processing capabilities of SLA printed models allow for additional finishing touches, such as sanding, painting, or coating, enhancing the final appearance and functionality of the printed object.

Another advantage of SLA 3D printers is their rapid prototyping capability. The speed at which these printers can cure resin layers means that complex models can be produced in a fraction of the time compared to traditional manufacturing methods. This rapid turnaround can significantly enhance product development cycles, enabling businesses to bring their ideas to market more quickly.

However, it is essential to consider the maintenance and operational aspects of SLA 3D printers. The use of liquid resin requires careful handling and safety precautions, as the material can be toxic before curing. Additionally, SLA printers generally necessitate a post-curing stage to fully harden the printed parts, which can involve using UV light to achieve the best results. Understanding these processes and implementing safety measures is crucial for anyone looking to dive into SLA printing.

In conclusion, SLA 3D printers offer a powerful solution for those seeking to produce high-quality, precise models across various industries. Their ability to deliver stunning detail and versatility in materials makes them an invaluable tool for designers, engineers, and hobbyists alike. As technology continues to evolve, the applications of SLA 3D printing are only set to expand further, promising exciting possibilities for innovation in the digital landscape.

One of the standout features of SLA 3D printers is their ability to produce parts with fine details that are often unattainable with other 3D printing methods. This makes SLA ideal for applications in jewelry making, dental models, and intricate engineering components. The level of accuracy provided by SLA technology ensures that even the most complex geometries can be printed with exceptional fidelity, which is critical for industries where precision is paramount.

In addition to their high detail resolution, SLA printers also offer a variety of resin options that can cater to specific needs. From tough, durable resins suitable for functional testing to flexible materials that can simulate rubber-like properties, the versatility of SLA resins helps designers and engineers innovate without limitations. Furthermore, the post-processing capabilities of SLA printed models allow for additional finishing touches, such as sanding, painting, or coating, enhancing the final appearance and functionality of the printed object.

Another advantage of SLA 3D printers is their rapid prototyping capability. The speed at which these printers can cure resin layers means that complex models can be produced in a fraction of the time compared to traditional manufacturing methods. This rapid turnaround can significantly enhance product development cycles, enabling businesses to bring their ideas to market more quickly.

However, it is essential to consider the maintenance and operational aspects of SLA 3D printers. The use of liquid resin requires careful handling and safety precautions, as the material can be toxic before curing. Additionally, SLA printers generally necessitate a post-curing stage to fully harden the printed parts, which can involve using UV light to achieve the best results. Understanding these processes and implementing safety measures is crucial for anyone looking to dive into SLA printing.

In conclusion, SLA 3D printers offer a powerful solution for those seeking to produce high-quality, precise models across various industries. Their ability to deliver stunning detail and versatility in materials makes them an invaluable tool for designers, engineers, and hobbyists alike. As technology continues to evolve, the applications of SLA 3D printing are only set to expand further, promising exciting possibilities for innovation in the digital landscape.

sla 3d printer

Recommended News

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Skype / WhatsApp: +86 592-5713513 / +86-13860126490

No.88-3, North Tongji Road, Xike County, Tong'an District, Xiamen, Fujian China

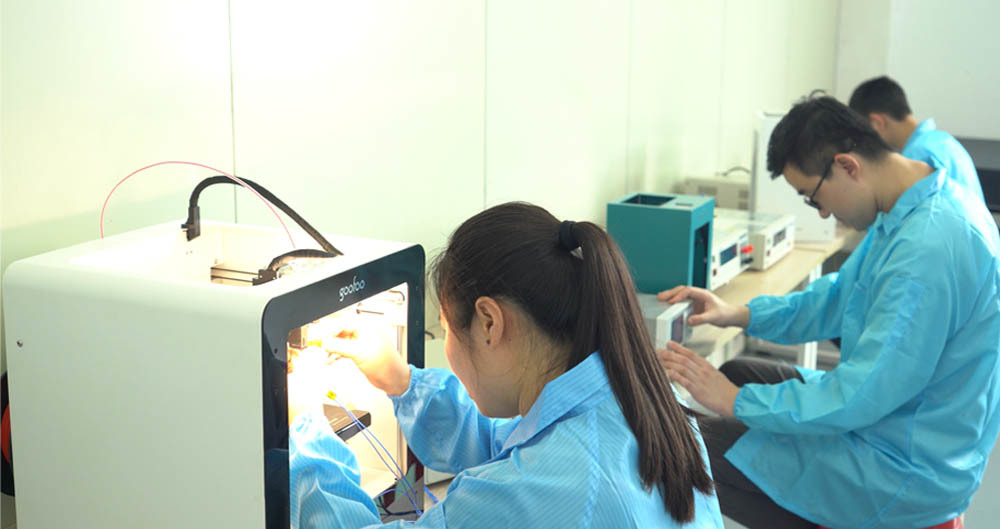

Xiamen Goofoo Technology Co., Ltd. All Rights Reserved 闽ICP备2022008070号-1 SEO 300.cn

Phone:+0086 592-5713513

Address: No.88-3, North Tongji Road, Xike County, Tong’an District, Xiamen, Fujian China

Email: sales@goofoo3d.com

We will give you feedback in time