All Categories

The Essential Guide to Understanding 3D Printer Extruders

2025-05-08 11:00

---

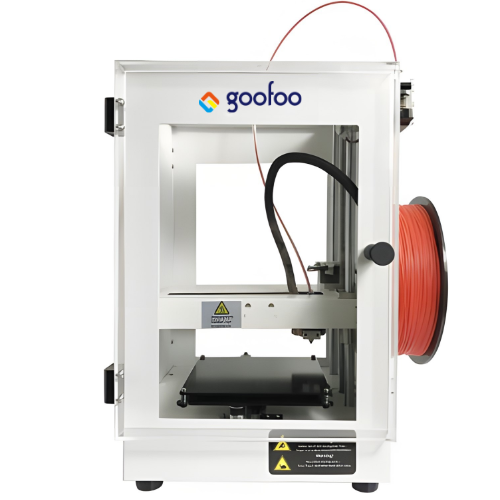

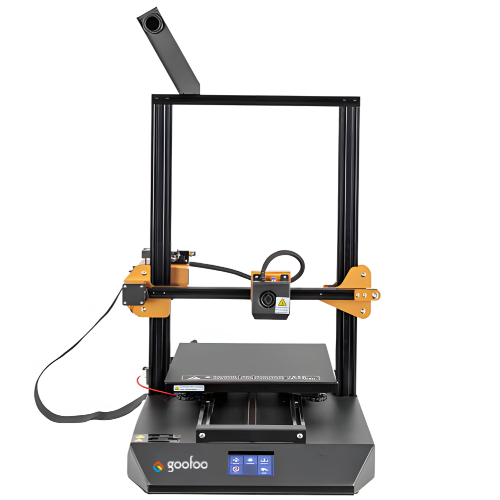

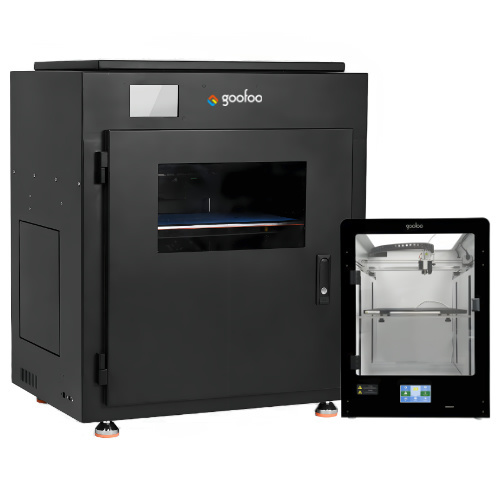

3D printing technology has revolutionized various industries, enabling the creation of complex structures with incredible precision. At the heart of this process is the 3D printer extruder, a critical component that plays a vital role in material deposition. Understanding how extruders work can significantly enhance your 3D printing experience.

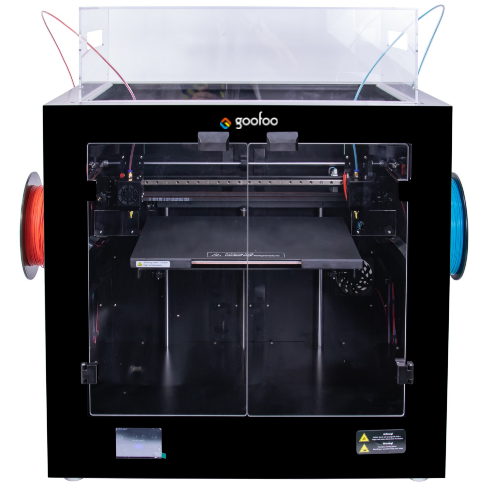

A 3D printer extruder is responsible for feeding the filament into the hot end, where it is melted and extruded through a nozzle to form the desired shape layer by layer. There are primarily two types of extruders: direct drive and Bowden.

Direct drive extruders are mounted directly on the print head, allowing for precise control over the filament's flow. This design is particularly advantageous for printing flexible materials, as it minimizes the distance between the drive gear and the nozzle. However, the additional weight on the print head can affect print speed and quality, especially for more intricate designs.

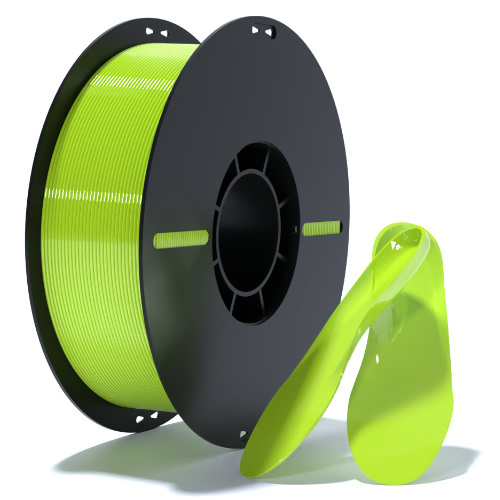

On the other hand, Bowden extruders utilize a tube to transport the filament from the motor to the hot end. This setup reduces the weight on the print head, enabling faster print speeds and more dynamic movements. However, Bowden extruders may struggle with flexible filaments due to the increased distance and friction in the tubing.

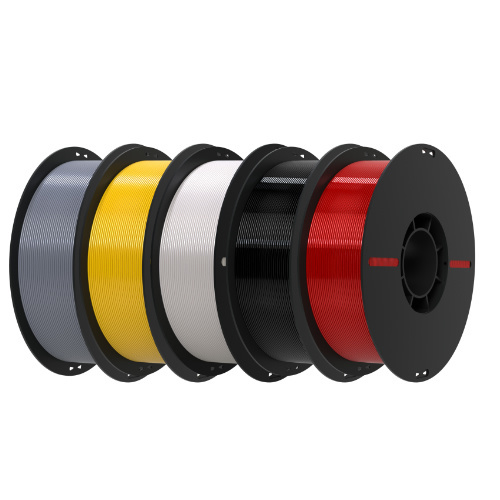

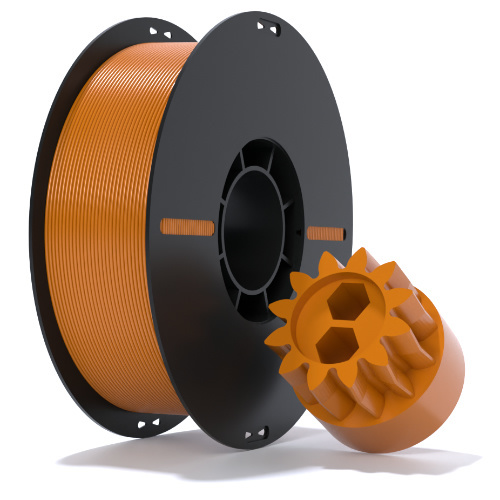

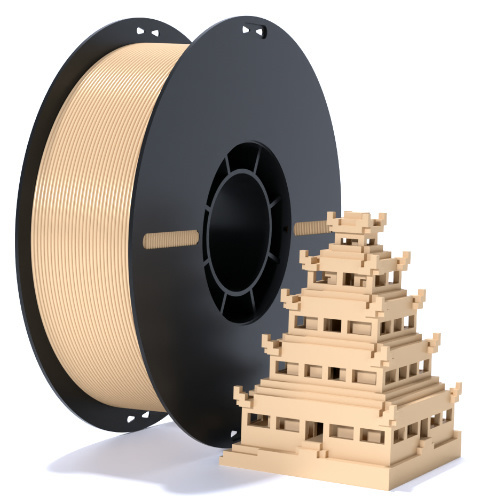

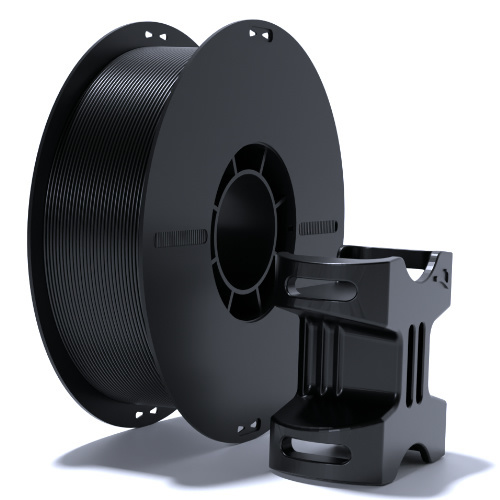

Filament choice is another crucial factor influenced by the extruder type. Different filaments, such as PLA, ABS, PETG, and TPU, require varying temperatures and extrusion speeds. It’s essential to ensure that the extruder is compatible with the specific filament you intend to use. Furthermore, the nozzle size and design also play a role in determining the layer resolution and print speed. Larger nozzles can extrude more material quickly but may compromise detail, while smaller nozzles provide finer resolution at the cost of speed.

Proper maintenance and calibration of the extruder are key to achieving optimal performance. Regularly checking for clogs or wear, ensuring the gears are clean and properly aligned, and calibrating the extrusion multiplier can prevent common printing issues such as under-extrusion or failed prints.

In conclusion, understanding the functionality and types of 3D printer extruders is essential for anyone involved in 3D printing. Whether you are a hobbyist or a professional, knowing how to select, maintain, and operate an extruder can lead to better print quality and more successful projects. Embracing the knowledge about extruders will empower you to explore the full potential of 3D printing technology.

3D printing technology has revolutionized various industries, enabling the creation of complex structures with incredible precision. At the heart of this process is the 3D printer extruder, a critical component that plays a vital role in material deposition. Understanding how extruders work can significantly enhance your 3D printing experience.

A 3D printer extruder is responsible for feeding the filament into the hot end, where it is melted and extruded through a nozzle to form the desired shape layer by layer. There are primarily two types of extruders: direct drive and Bowden.

Direct drive extruders are mounted directly on the print head, allowing for precise control over the filament's flow. This design is particularly advantageous for printing flexible materials, as it minimizes the distance between the drive gear and the nozzle. However, the additional weight on the print head can affect print speed and quality, especially for more intricate designs.

On the other hand, Bowden extruders utilize a tube to transport the filament from the motor to the hot end. This setup reduces the weight on the print head, enabling faster print speeds and more dynamic movements. However, Bowden extruders may struggle with flexible filaments due to the increased distance and friction in the tubing.

Filament choice is another crucial factor influenced by the extruder type. Different filaments, such as PLA, ABS, PETG, and TPU, require varying temperatures and extrusion speeds. It’s essential to ensure that the extruder is compatible with the specific filament you intend to use. Furthermore, the nozzle size and design also play a role in determining the layer resolution and print speed. Larger nozzles can extrude more material quickly but may compromise detail, while smaller nozzles provide finer resolution at the cost of speed.

Proper maintenance and calibration of the extruder are key to achieving optimal performance. Regularly checking for clogs or wear, ensuring the gears are clean and properly aligned, and calibrating the extrusion multiplier can prevent common printing issues such as under-extrusion or failed prints.

In conclusion, understanding the functionality and types of 3D printer extruders is essential for anyone involved in 3D printing. Whether you are a hobbyist or a professional, knowing how to select, maintain, and operate an extruder can lead to better print quality and more successful projects. Embracing the knowledge about extruders will empower you to explore the full potential of 3D printing technology.

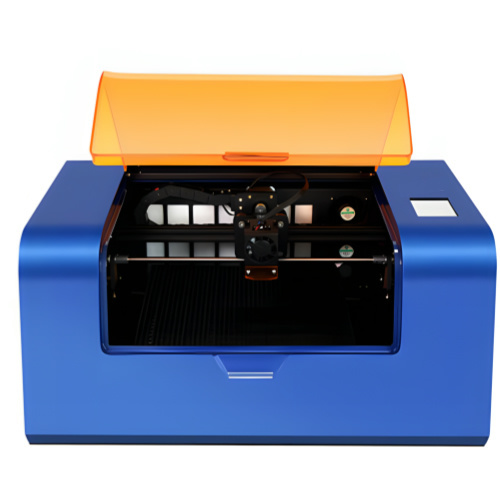

3d printer extruder

Recommended News

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Skype / WhatsApp: +86 592-5713513 / +86-13860126490

No.88-3, North Tongji Road, Xike County, Tong'an District, Xiamen, Fujian China

Xiamen Goofoo Technology Co., Ltd. All Rights Reserved 闽ICP备2022008070号-1 SEO 300.cn

Phone:+0086 592-5713513

Address: No.88-3, North Tongji Road, Xike County, Tong’an District, Xiamen, Fujian China

Email: sales@goofoo3d.com

We will give you feedback in time