The Future of Manufacturing: Exploring 3D Printers for Metal

2025-06-09 10:40

The rise of 3D printing technology has revolutionized numerous sectors, and one of the most exciting advancements is the capability to print with metal. 3D printers for metal are paving the way for innovative production techniques, leading to enhanced efficiency, customization, and sustainability in manufacturing. This article delves into the essential aspects of metal 3D printing, highlighting its significance in the landscape of computer digital products.

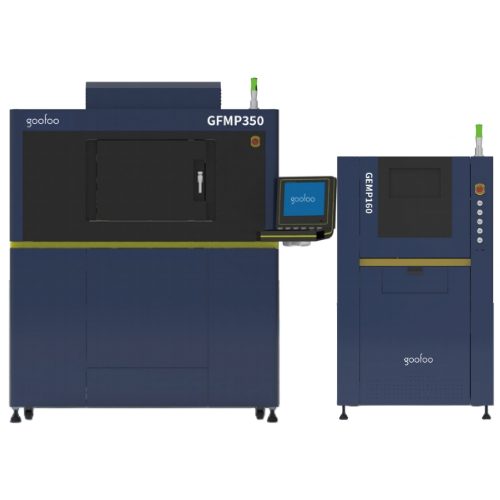

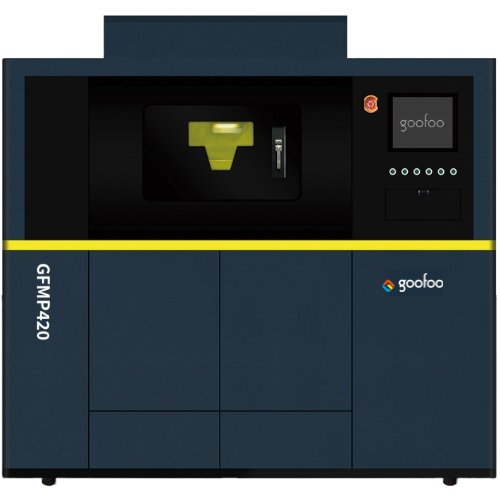

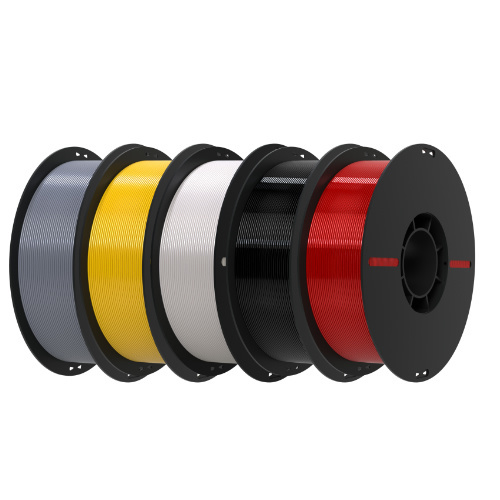

Metal 3D printers utilize various technologies, including direct metal laser sintering (DMLS) and selective laser melting (SLM). These processes involve the layer-by-layer addition of metal powders, which are fused together using lasers to create complex geometries that traditional manufacturing methods often cannot achieve. This ability to produce intricate designs not only streamlines production but also minimizes material waste, contributing to a more sustainable manufacturing process.

One of the most significant advantages of using 3D printers for metal is the reduction in lead times. Traditional methods often require extensive tooling and setup, whereas metal 3D printing allows for rapid prototyping. This means that professionals can quickly iterate designs and test new concepts without the long wait times typically associated with conventional manufacturing. This speed is particularly beneficial in industries where innovation is crucial, such as aerospace, automotive, and medical devices.

Furthermore, 3D printing with metal offers unparalleled design flexibility. Engineers and designers can create complex structures that are lighter and stronger than those produced by traditional methods. For instance, lattice structures can be printed, which provide excellent strength-to-weight ratios. This capability is instrumental in industries where performance and efficiency are paramount, making 3D printers for metal a game-changer.

Another aspect worth noting is the potential for customization. In industries where bespoke components are often required, such as the healthcare sector for patient-specific implants, metal 3D printers can produce tailored solutions that meet precise specifications. This level of customization not only enhances functionality but also improves patient outcomes.

Despite the many benefits, it's essential to consider the challenges associated with 3D printing for metal. The technology can require substantial initial investments in equipment and expertise. Additionally, the post-processing steps, such as heat treatment and surface finishing, can add complexity to the workflow. Therefore, organizations looking to adopt this technology should carefully evaluate their capabilities and needs.

In conclusion, 3D printers for metal represent a significant evolution in the manufacturing landscape, offering numerous advantages, including reduced lead times, design flexibility, and customization potential. As more industries recognize the benefits of this technology, it is poised to redefine traditional manufacturing paradigms, making it an exciting area for professionals to explore. Embracing metal 3D printing can lead to innovative solutions and enhanced productivity in various applications, showcasing the future of manufacturing.

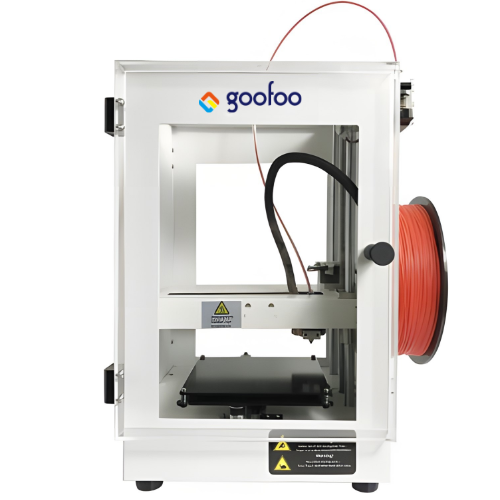

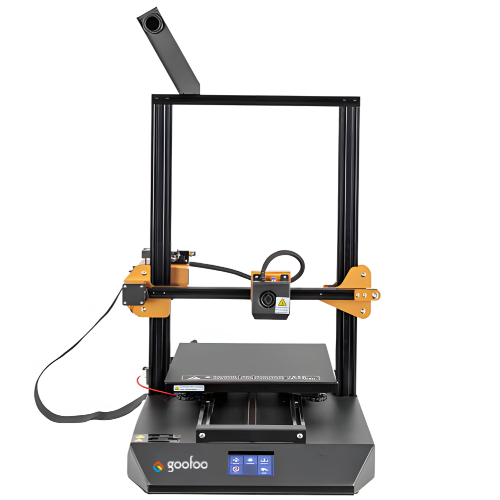

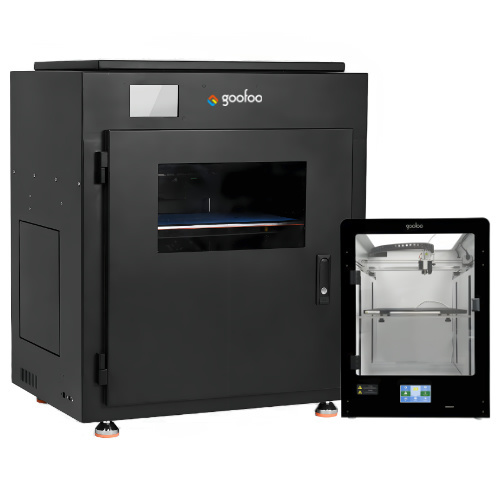

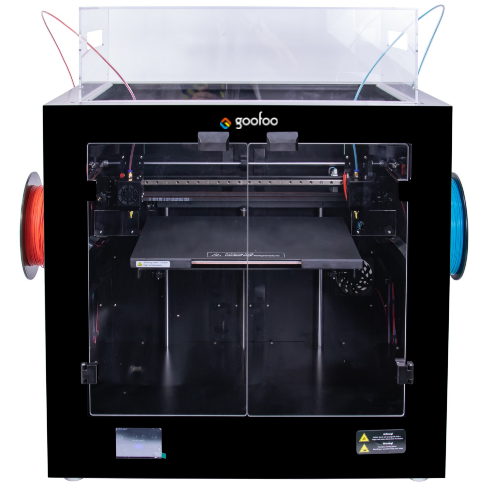

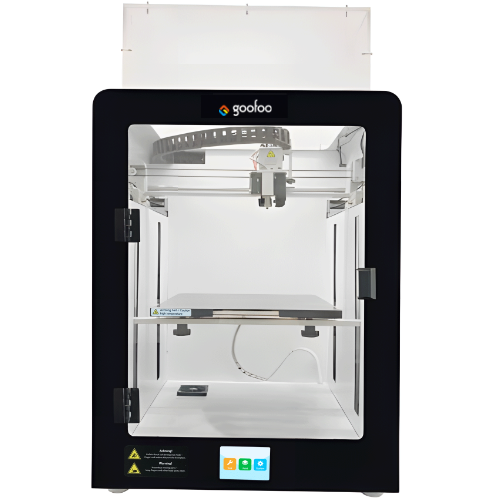

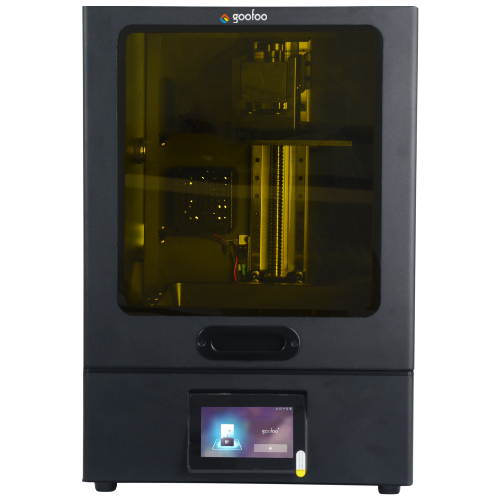

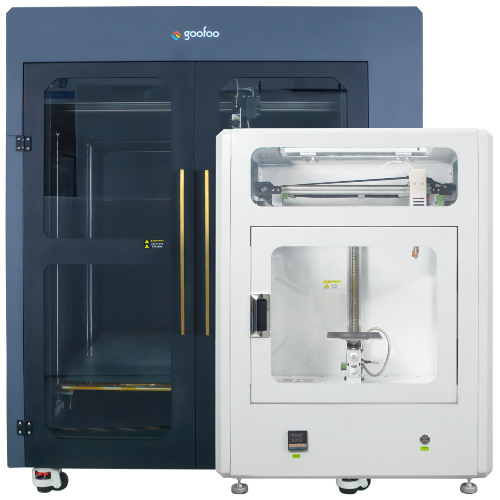

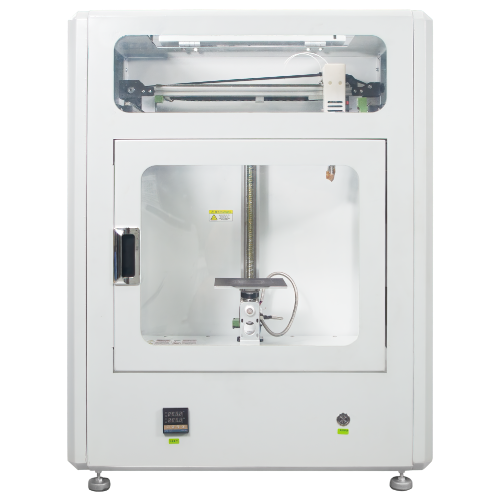

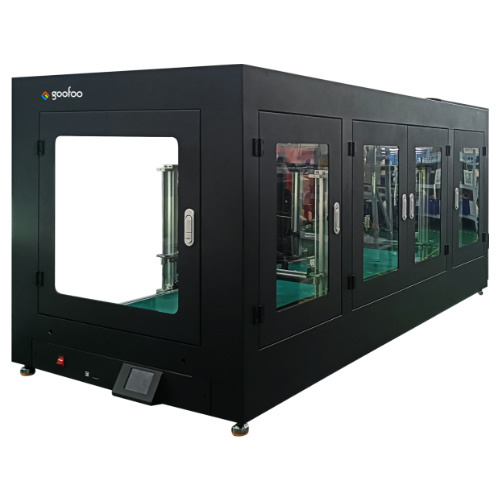

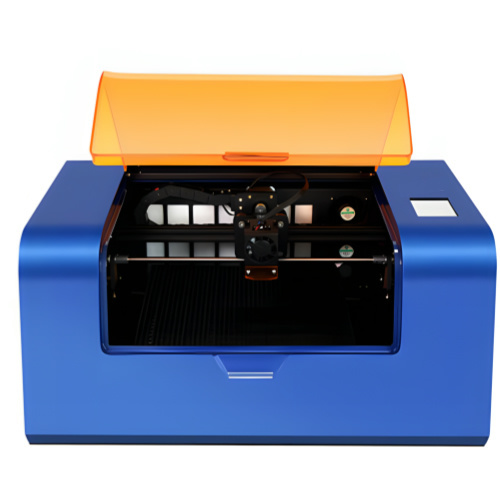

3d printer for metal

Recommended News

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Skype / WhatsApp: +86 592-5713513 / +86-13860126490

No.88-3, North Tongji Road, Xike County, Tong'an District, Xiamen, Fujian China

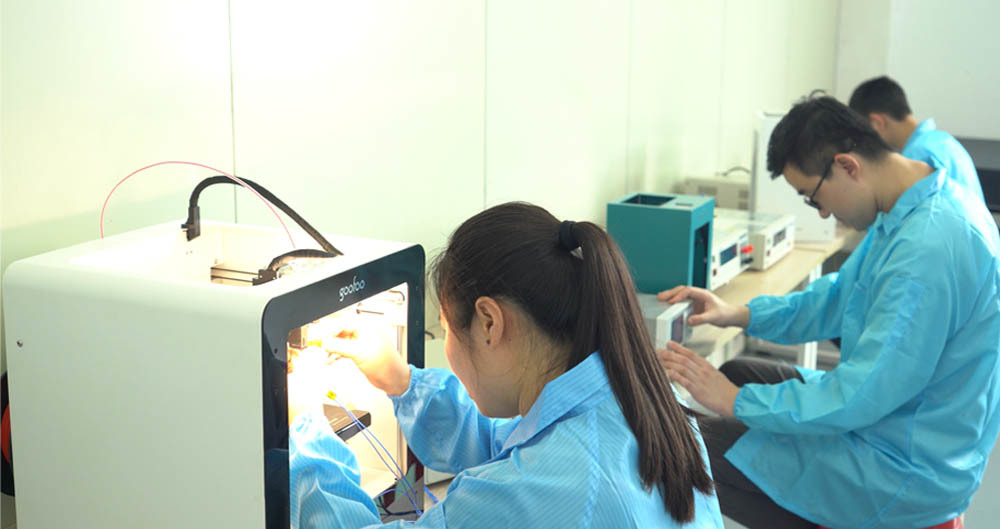

Xiamen Goofoo Technology Co., Ltd. All Rights Reserved 闽ICP备2022008070号-1 SEO 300.cn

Phone:+0086 592-5713513

Address: No.88-3, North Tongji Road, Xike County, Tong’an District, Xiamen, Fujian China

Email: sales@goofoo3d.com

We will give you feedback in time