All Categories

Exploring Innovation: Cutting-Edge Materials for 3D Printing Enthusiasts

2025-08-16 22:00

Exploring Innovation: Cutting-Edge Materials for 3D Printing Enthusiasts

Table of Contents

- 1. Introduction to 3D Printing Materials

- 2. The Importance of Material Selection in 3D Printing

- 3. Types of Cutting-Edge Materials for 3D Printing

- 3.1 Bioplastics: The Eco-Friendly Option

- 3.2 Metal Composites: Strength Meets Versatility

- 3.3 Advanced Ceramics: Heat and Wear Resistance

- 3.4 Carbon Fiber Reinforced Plastics: Lightweight and Strong

- 3.5 Specialty Filaments: The Unique Offerings

- 4. Applications of Cutting-Edge 3D Printing Materials

- 5. The Future of 3D Printing Materials

- 6. Challenges in Material Development

- 7. Conclusion

- 8. FAQs

1. Introduction to 3D Printing Materials

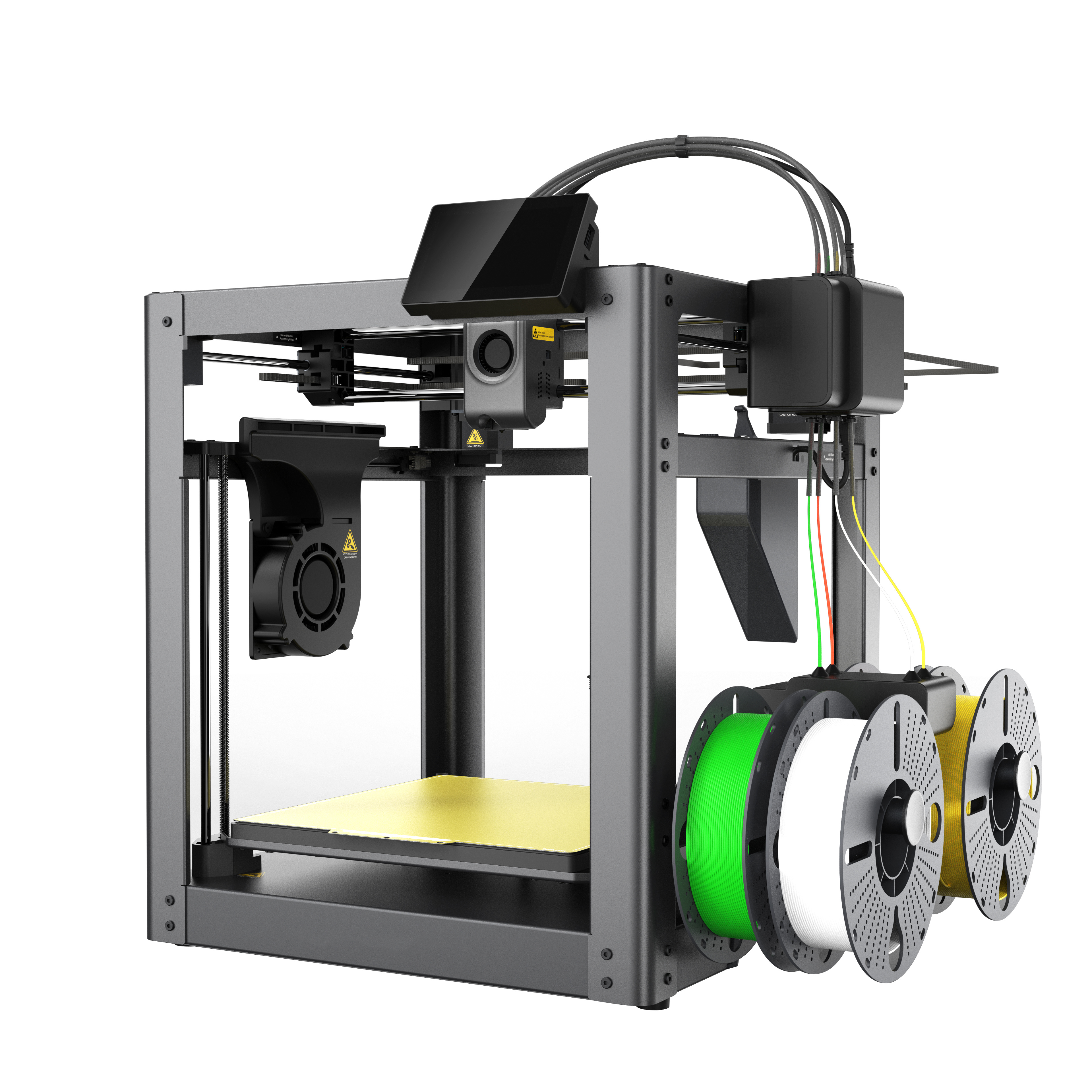

The evolution of 3D printing technology has opened the door to a myriad of possibilities, particularly in the realm of materials. As 3D printing becomes more integrated into various industries, understanding the **cutting-edge materials** available is essential for enthusiasts and professionals alike. This article delves into innovative materials that are revolutionizing the 3D printing landscape, enabling creators to transform their visions into reality.

2. The Importance of Material Selection in 3D Printing

The **selection of materials** in 3D printing is a critical component that significantly impacts the final product's performance, durability, and aesthetic appeal. Choosing the right material is not merely a technical decision; it influences the entire design process and the usability of the final print. As 3D printing applications expand, so does the need for materials that can withstand varying conditions while offering unique properties.

3. Types of Cutting-Edge Materials for 3D Printing

As innovations continue to emerge, here are some of the most exciting categories of materials currently shaping the future of 3D printing:

3.1 Bioplastics: The Eco-Friendly Option

Bioplastics, derived from renewable sources like cornstarch and sugarcane, are becoming increasingly popular among environmentally-conscious makers. These materials not only reduce **reliance on fossil fuels** but also provide an opportunity for sustainable manufacturing practices. Notable types of bioplastics include PLA (Polylactic Acid), which is biodegradable and easy to print, and PHA (Polyhydroxyalkanoates), which boasts excellent mechanical properties.

3.2 Metal Composites: Strength Meets Versatility

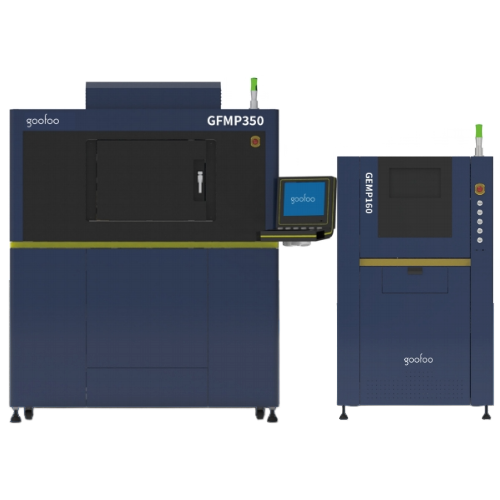

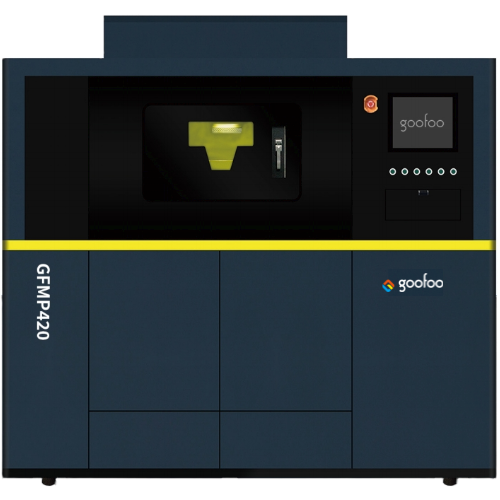

For applications demanding high strength and durability, **metal composites** are a game changer. Materials such as stainless steel, titanium, and aluminum can be printed using techniques like Direct Metal Laser Sintering (DMLS). These metal composites are ideal for industries requiring robust components, such as aerospace and automotive. Innovations in powder metallurgy have led to the development of lighter, stronger materials that can withstand extreme environments.

3.3 Advanced Ceramics: Heat and Wear Resistance

Ceramic materials are often overlooked in the realm of 3D printing, yet they offer remarkable properties such as high-temperature resistance and excellent wear characteristics. Advanced ceramics can be used in applications ranging from **aerospace components** to dental implants. Processes like Binder Jetting allow for the production of intricate designs that were previously unattainable with traditional ceramic manufacturing methods.

3.4 Carbon Fiber Reinforced Plastics: Lightweight and Strong

Carbon fiber reinforced plastics (CFRPs) are making waves in the 3D printing community owing to their exceptional strength-to-weight ratio. These materials, often combined with standard thermoplastics during the extrusion process, are perfect for creating lightweight structures without compromising on durability. Industries such as sports equipment, automotive, and robotics benefit tremendously from CFRPs, as they allow for more efficient designs and material usage.

3.5 Specialty Filaments: The Unique Offerings

Specialty filaments provide unique functionalities that cater to specific needs. For instance, **conductive filaments** enable the creation of electronic components, while flexible filaments like TPU (Thermoplastic Polyurethane) are ideal for products requiring elasticity. These materials push the boundaries of what can be achieved through 3D printing, enticing makers to explore uncharted territories of creativity.

4. Applications of Cutting-Edge 3D Printing Materials

Understanding where these cutting-edge materials apply can illuminate their potential. The following sectors have seen significant impacts due to advancements in 3D printing materials:

- Aerospace: Reducing weight while maintaining structural integrity is paramount.

- Medical: Customized implants and prosthetics tailored to individual patients.

- Automotive: Prototyping and production of lightweight components to enhance fuel efficiency.

- Consumer Goods: Rapid production of customized products, from jewelry to household items.

- Architecture: Innovative building models and components that push design boundaries.

5. The Future of 3D Printing Materials

As technology advances, the future of **3D printing materials** looks promising. Research is ongoing to develop materials that combine multiple desirable properties, such as flexibility, strength, and sustainability. For example, materials that can self-heal or change properties in response to environmental conditions are being explored. Additionally, the integration of AI and machine learning into the material development process will likely result in smarter materials tailored for specific applications.

6. Challenges in Material Development

Despite the progress made, the development of cutting-edge materials for 3D printing faces several challenges. These include:

- Cost: Advanced materials can be more expensive than traditional options, which may hinder widespread adoption.

- Manufacturing Limitations: Not all materials are compatible with existing 3D printing technologies.

- Regulatory Hurdles: Industries like aerospace and medical face strict regulations regarding material safety and performance.

- Environmental Impact: While bioplastics are a step forward, other materials may still pose environmental challenges.

7. Conclusion

The landscape of 3D printing materials is constantly evolving, driven by innovation and the demand for unique applications. By embracing **cutting-edge materials** like bioplastics, metal composites, and advanced ceramics, enthusiasts and professionals can unlock new possibilities in their projects. The future promises even more exciting developments, paving the way for sustainable practices and advanced functionalities in 3D printing.

8. FAQs

What are some common materials used in 3D printing?

Some common materials include PLA, ABS, PETG, nylon, and TPU, alongside more advanced options like metal composites and ceramics.

Can bioplastics be used for functional 3D printing?

Yes, bioplastics like PLA can be used for functional 3D printing, particularly for prototypes and items that don’t require extreme durability.

What industries benefit from metal 3D printing?

Industries such as aerospace, automotive, and medical significantly benefit from metal 3D printing due to the high strength and durability of metal components.

Are there 3D printing materials that conduct electricity?

Yes, there are conductive filaments available for 3D printing that can be used for electronic components and circuits.

What challenges do 3D printing materials face in the market?

Challenges include high costs, compatibility with existing technologies, regulatory hurdles, and environmental considerations.

This comprehensive exploration reveals that cutting-edge materials are not just changing the way we approach 3D printing, but also expanding its possibilities in numerous industries. Embracing these innovations allows creators to push the boundaries of what is possible, leading to exciting and sustainable advancements in technology.

best 3d printer

Recommended News

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Skype / WhatsApp: +86 592-5713513 / +86-13860126490

No.88-3, North Tongji Road, Xike County, Tong'an District, Xiamen, Fujian China

Xiamen Goofoo Technology Co., Ltd. All Rights Reserved 闽ICP备2022008070号-1 SEO 300.cn

Phone:+0086 592-5713513

Address: No.88-3, North Tongji Road, Xike County, Tong’an District, Xiamen, Fujian China

Email: sales@goofoo3d.com

We will give you feedback in time