All Categories

The Future of 3D Printing: Exploring the Advantages of Resin Printers

2025-08-12 17:40

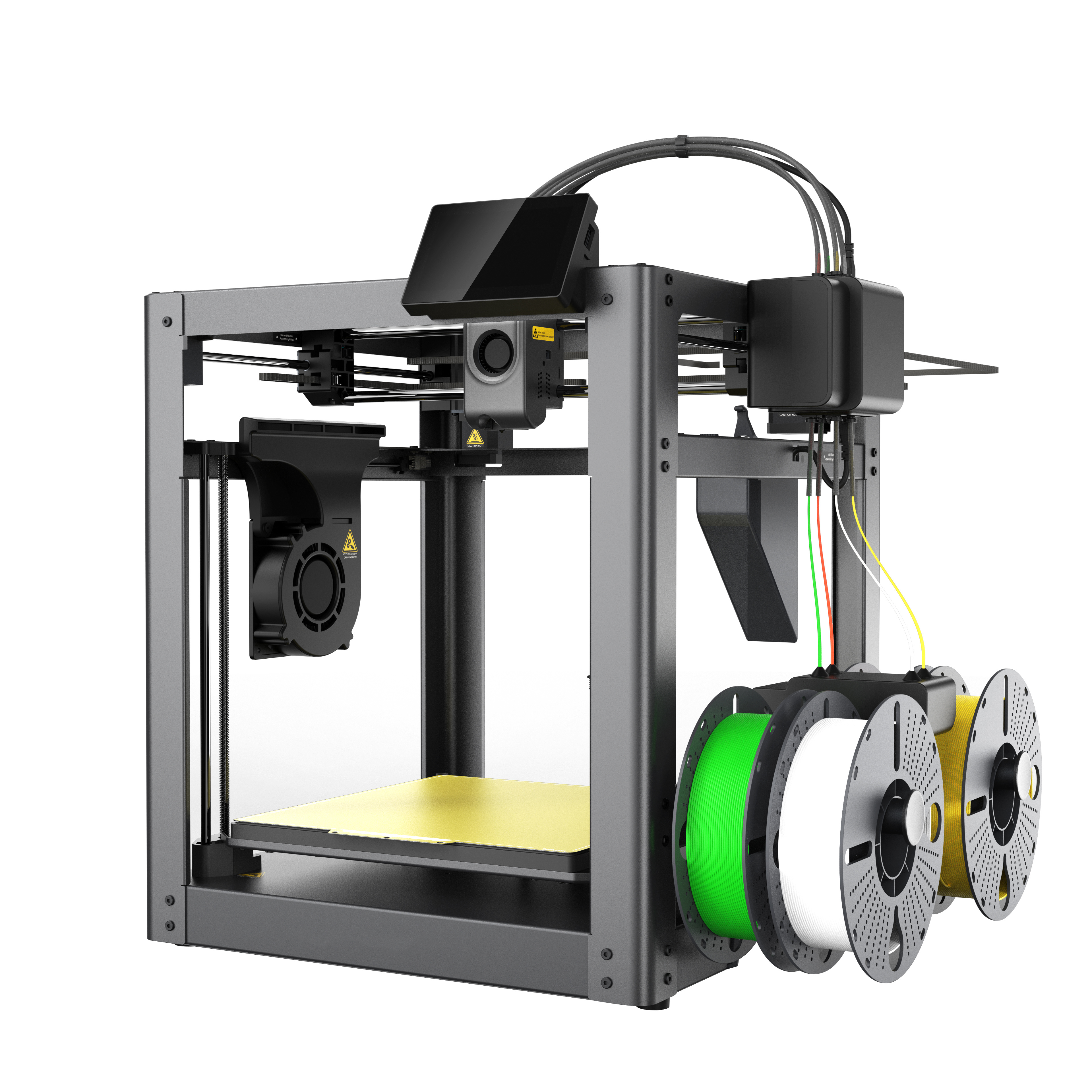

In the realm of additive manufacturing, 3D printers with resin have emerged as a game-changer, offering unique advantages that set them apart from traditional filament-based printers. These printers utilize photopolymer resin, which hardens when exposed to UV light, enabling the creation of intricate, high-resolution models. This article explores the technical aspects and benefits of resin 3D printing, ideal for those looking to enhance their understanding of this innovative technology.

One of the most significant advantages of 3D printers with resin is their ability to produce highly detailed prints. The layer thickness in resin printing can be as fine as 25 microns, allowing for exceptional precision and smooth surface finishes. This capability is particularly beneficial for industries such as jewelry, dentistry, and miniature modeling, where fine details are crucial. Moreover, the range of available resins has expanded, including options for flexibility, high-temperature resistance, and biocompatibility, enhancing the versatility of these printers.

Another key benefit is the speed of printing. While traditional FDM (Fused Deposition Modeling) printers may take hours to produce a detailed model, resin printers can accomplish similar tasks in significantly less time. This efficiency is attributed to the fact that resin printing often involves curing entire layers simultaneously rather than extruding material line by line. For businesses and hobbyists alike, this time-saving aspect can lead to increased productivity and faster prototyping cycles.

In terms of usability, 3D printers with resin typically feature user-friendly interfaces and intuitive software. Many models come equipped with touchscreen displays and pre-configured print settings, making them accessible even to those new to 3D printing. Additionally, the post-processing steps, although necessary, can be streamlined with the right tools, such as wash stations and curing stations, further simplifying the workflow.

However, it’s essential to acknowledge some challenges associated with resin printing. The handling of liquid resin requires safety precautions, including gloves and masks, as certain resins can be toxic or irritating to the skin. Moreover, the curing process can produce fumes, necessitating proper ventilation. Users must also be aware of the maintenance required for these printers, as the resin vat and components need regular cleaning to ensure optimal performance.

In conclusion, 3D printers with resin are revolutionizing the landscape of additive manufacturing, offering high precision, speed, and versatility. Their technological advancements cater to a wide range of applications, making them an invaluable tool for professionals across various sectors. As this technology continues to evolve, embracing the capabilities of resin printing can open new doors for creativity and innovation in design and production.

One of the most significant advantages of 3D printers with resin is their ability to produce highly detailed prints. The layer thickness in resin printing can be as fine as 25 microns, allowing for exceptional precision and smooth surface finishes. This capability is particularly beneficial for industries such as jewelry, dentistry, and miniature modeling, where fine details are crucial. Moreover, the range of available resins has expanded, including options for flexibility, high-temperature resistance, and biocompatibility, enhancing the versatility of these printers.

Another key benefit is the speed of printing. While traditional FDM (Fused Deposition Modeling) printers may take hours to produce a detailed model, resin printers can accomplish similar tasks in significantly less time. This efficiency is attributed to the fact that resin printing often involves curing entire layers simultaneously rather than extruding material line by line. For businesses and hobbyists alike, this time-saving aspect can lead to increased productivity and faster prototyping cycles.

In terms of usability, 3D printers with resin typically feature user-friendly interfaces and intuitive software. Many models come equipped with touchscreen displays and pre-configured print settings, making them accessible even to those new to 3D printing. Additionally, the post-processing steps, although necessary, can be streamlined with the right tools, such as wash stations and curing stations, further simplifying the workflow.

However, it’s essential to acknowledge some challenges associated with resin printing. The handling of liquid resin requires safety precautions, including gloves and masks, as certain resins can be toxic or irritating to the skin. Moreover, the curing process can produce fumes, necessitating proper ventilation. Users must also be aware of the maintenance required for these printers, as the resin vat and components need regular cleaning to ensure optimal performance.

In conclusion, 3D printers with resin are revolutionizing the landscape of additive manufacturing, offering high precision, speed, and versatility. Their technological advancements cater to a wide range of applications, making them an invaluable tool for professionals across various sectors. As this technology continues to evolve, embracing the capabilities of resin printing can open new doors for creativity and innovation in design and production.

3d printer with resin

Recommended News

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Skype / WhatsApp: +86 592-5713513 / +86-13860126490

No.88-3, North Tongji Road, Xike County, Tong'an District, Xiamen, Fujian China

Xiamen Goofoo Technology Co., Ltd. All Rights Reserved 闽ICP备2022008070号-1 SEO 300.cn

Phone:+0086 592-5713513

Address: No.88-3, North Tongji Road, Xike County, Tong’an District, Xiamen, Fujian China

Email: sales@goofoo3d.com

We will give you feedback in time