How do you use industrial 3D printers in your company?

In the era of Industry 4.0, more and more enterprises decide to implement 3D printing to optimize their business processes.

The use of FDM technology is usually one of the most beneficial solutions in the production of machine, production line and tool spare parts. In addition, it is one of the fastest ways to manufacture prototypes, including those with complex geometric structures.

3D printers can significantly reduce production time, making it possible for companies to improve their competitiveness.

Use 3D printing to shorten the implementation time

A Polish company used 3D printers to produce prototypes of transport pallets, which were ultimately used to secure finished products during production. Prototype creation time plays a key role in the execution of final customer orders.

The creation of 3D printing prototypes can speed up the programming process of industrial robots located on production lines. The implementation time of the new production line in the automobile factory has even been shortened by three weeks.

3D printing is a faster technology than traditional methods (such as various types of machining) for making prototypes with complex geometric shapes.

Evaluation of ergonomics, dimensions, and accuracy of a prototype

A medical equipment supplier created a new patient monitor model case using 3D printing technology. Project validation can be performed by installing the target component in the 3D print housing.

The final details obtained using the injection technique do not require any correction. The documents approving the production of injection molds are very effective.

The production process of models and prototypes manufactured by external enterprises takes at least one month. The prototype patient monitor was received within 5 days, reducing the 25 day delivery cycle.

The element of a production tooling

AMS Systems specializes in machine design and manufacturing. The company uses 3D printers to make shells for acquisition and verification sensors in daily work. The Pick to Light system is finally installed in the production stage.

The optimization of the sensor components and the improvement of the stability of the Pick to Light sensor are the main goals of the 3D printing housing.

Threads, that is, shell elements, are usually produced incorrectly by external companies, which leads to problems with the matching of details. This resulted in customer complaints and additional replacement costs. Housing printing improves the stability of the sensor and increases its mechanical strength. The use of 3D printers shortens the machine's completion time, allowing customers to complete orders in 7 days faster.

Verification of the correctness of the prototype execution

A fire truck manufacturer used 3DGene INDUSTRY F340 to create a life size 3D model of the manifold at a 1:1 scale. The company can check the ergonomics, functionality and durability of the prototype through assembly.

In the process of rapid prototyping, it is still very difficult to obtain perfect products, especially in ergonomics. Thanks to 3D printers, the company was able to produce models that were exactly the same as the expected real details. Even in the early design phase, different departments of the company can introduce specific changes.

Testing of tooling design

An aircraft engine parts manufacturer uses a 3D printer to produce expansion sleeves for lathe tools every day for fastening aircraft parts during machining.

Producing parts and prototypes on CNC machines is associated with high costs and long project implementation processes. The application of 3D printing technology has helped the company reduce production costs and accelerate the production of necessary parts.

3D printing is also used in the testing phase of the new solution. Before the starting element starts to work, make its prototype and conduct processing test on CNC machine tool. The print prototype allows you to check the kinematics and all motions of the machine in the machining space on the 3D printout. After working on the correct parts, the whole process has been prepared, the machine has been calibrated, and the risk of inaccurate setting is greatly reduced.

Mock-ups of industrial machines

A machinery manufacturer used in the mining industry has a life size machine that can even weigh several tons, which is why the enterprise decided to print eight models in 3D. The model can be further processed, smoothed and painted with ABS plastic materials.

3D printing for industrial models is the simplest and cheapest solution, which allows you to show the machine to customers or investors without transportation.

Designing and construction of racing cars

A student research team at Krakow AGH University of Science and Technology made a prototype of the steering knuckle, which is a part of the racing suspension and is used for the production of auto parts, when building the equation student car.

The 3D printout is used to check the design topology of the knuckle. This project is designed to reduce weight and increase the stiffness of the elements.

Typically, joints are made of aluminum by milling. The significant change of part geometry makes it impossible to process this complex shape routinely. 3D printing enables students to obtain joint prototypes with complex geometric shapes at a very low cost in just 2 days.

Test of mecanum wheels mounted in a robot

A company has introduced a new type of McNaum wheel, which is an important part of mobile robots..

Thanks to 3D printing technology, they can verify and improve the designed wheel model. They can launch new products faster, more efficient and cheaper than usual. In the research and development work, the possibility of simple and continuous verification of each phase of the project is very important. Especially in the prototype phase, costly errors may occur.

The cost of making prototypes using other available technologies is several times higher. This is due to the complex geometry - the wheel consists of up to 12 elements, nine of which are made of rubber.

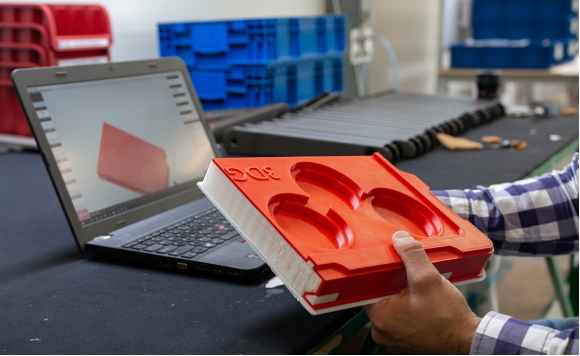

Complex geometry dies

A company manufactures plastic molds that are eventually used as components in production lines. At present, all molds used to base or inspect products on the production line are made with 3D printers.

Before purchasing specialized FDM machines, the company faced several challenges. As far as templates are concerned, they use similar technologies to compete very fiercely, so they offer products at similar prices. On the other hand, the prototype of elastomer parts is manufactured on a milling machine, which is expensive and occupies machines that should be used for different orders.

The investment in 3D printing has proved to be an ideal solution. Today, the company prints durable, damage resistant molds with complex geometry.

Drone housing

A company used 3D printing technology to make components for its UAV and a shell for the UAV to protect the parts inside the machine from mechanical damage. Because of the small scale of production, engineers cannot use more expensive traditional technology to build houses.

The enclosure is made of carbon fiber reinforced material for 3D printing. Thanks to this solution, the rigidity and durability of parts are improved. The 3D printout is characterized by its lightweight and hard structure. The company can easily install cameras, LEDs and alarms there. After the previous mild test, the prototype passed the impact test.

Reprint from https://3dgence.com/3dnews/10-applications-of-industrial-3d-printer/

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Skype / WhatsApp: +86 592-5713513 / +86-13860126490

No.88-3, North Tongji Road, Xike County, Tong'an District, Xiamen, Fujian China

Xiamen Goofoo Technology Co., Ltd. All Rights Reserved 闽ICP备2022008070号-1 SEO 300.cn

Phone:+0086 592-5713513

Address: No.88-3, North Tongji Road, Xike County, Tong’an District, Xiamen, Fujian China

Email: sales@goofoo3d.com

We will give you feedback in time